Installation And Commissioning Instructions for Air Flow Screening Machine

Airflow screen is also called cyclone screen. Common airflow screen models include vertical airflow screen and horizontal airflow screen. Airflow screen is a new type of high-precision screening equipment that screens fine powder with a mesh. It has been widely used in chemical, pharmaceutical, food, paper, metallurgy, building materials, rubber, machinery and other industries. The air flow screen (cyclone screen) has high screening efficiency, large output, accurate screening fineness, no over-diameter mixing phenomenon, long screen life, wide range of fineness (80-500 mesh), and a fully enclosed structure. No dust spills, low energy consumption, low noise, continuous operation, convenient maintenance, etc.

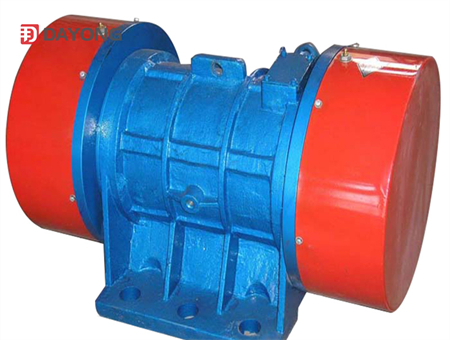

As a new type of high-precision screening equipment, the air flow screen should pay more attention to daily maintenance and maintenance than ordinary vibrating screening equipment. When using the equipment, it should be used strictly in accordance with the air flow screen instruction manual provided with the Dayong vibration. The method operates correctly. The correct use method can improve the working efficiency of the air screen, and can effectively increase the service life of the air screen. This article mainly explains how to install and debug the airflow screen (cyclone screen):

1. Installation of air flow screening machine

1). The air screen should be installed on a dedicated foundation fixed with embedded bolts as much as possible. If a dedicated foundation cannot be provided for the air screen due to special reasons, a vibration-proof rubber plate should also be laid between the workbench and the equipment base;

2). The air flow screen must be connected to a safe and reliable grounding protection line before it is energized and used;

3). After the installation of the air flow screening machine is completed, all the transportation fastening bolts must be removed before it can be started up.

2. Installation of airflow screen mesh.

1). To ensure the correct installation of the equipment screen, the air-flow screening machine screen is installed in a cylindrical shape, and the upper and lower ends of the screen are respectively fixed by steel wire ropes;

2). Use 810 adhesive at the screen joints to bond 30-50mm;

3). When fixing the wire ropes at both ends of the screen, adjust the screen while tightening it. The screen must be uniformly tensioned without pleating or twisting.