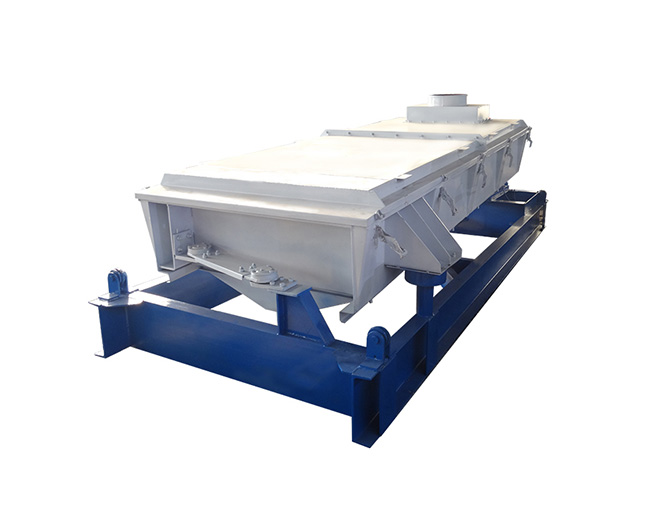

| Model | Screen Surface Area(mm) |

Feeding Size (mm) |

Amplitude (mm) |

Frequency (r/min) |

Motor Model | Power (kW) |

Layer |

| PXZS1224 | 1200x2400 | <15 | 75-90 | 1450 | Y132S-4 | 3-5.5 | 1-3 |

| PXZS1230 | 1200x3000 | <15 | 75-90 | 1450 | |||

| PXZS1236 | 1200x3600 | <15 | 75-90 | 1450 | |||

| PXZS1524 | 1500x2400 | <15 | 75-90 | 1450 | |||

| PXZS1530 | 1500x3000 | <15 | 75-90 | 1450 | |||

| PXZS1536 | 1500x3600 | <15 | 75-90 | 1450 | |||

| PXZS1830 | 1800x3000 | <20 | 75-90 | 750 | Y160L-8 | 5.5-7.5 | |

| PXZS1836 | 1800x3600 | <20 | 75-90 | 750 | |||

| PXZS1840 | 1800x4000 | <20 | 75-90 | 750 | |||

| PXZS2036 | 2000x3600 | <20 | 75-90 | 750 | |||

| PXZS2040 | 2000x4000 | <20 | 75-90 | 750 |