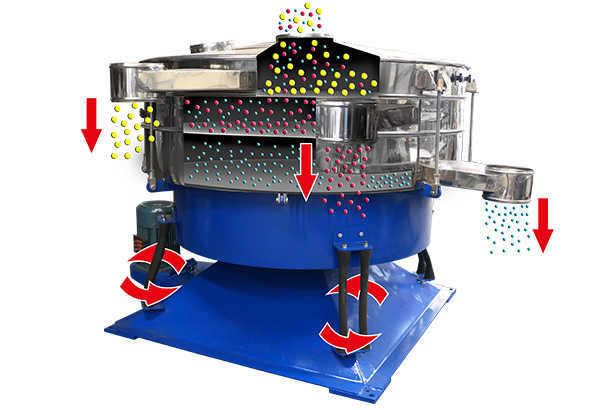

Application

Tumbler screen can sieve material that easily damaged or out of shape, such as ball, cylinder, and piece shape material.It is widely used in different fields, such as chemical industry, pharmaceutical industry, food & perfumery plant, plastic industry, sugar and salt industry, etc.

1. Chemical industry: resin pigment, medicine, grease, paint, palette, etc.

2. Abrasive material and ceramic industry: building sand, mica, alumina, abrasive, refractory material, slurry, etc.

3. Food industry: sugar, salt, alkali, gourmet powder, starch, milk powder, yeast powder, pollen, food additive, bean milk, juice, etc.

4. Paper-making industry: coated slurry, exhaust liquid, paper making liquid and waste water reclamation, etc.

5. Metallurgy and mining industry: quartz sand, ore, titanium oxide, zinc oxide, etc.

6. Mechanical industry: casting sand, powder metallurgy, electromagnetic material and metal powder, etc.