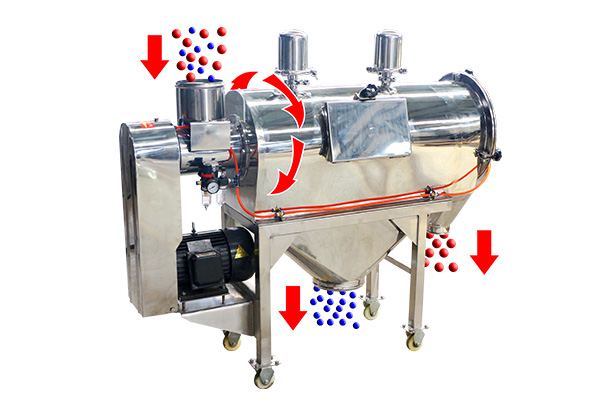

Application

This machine is available in various industries such as starch, glucose powder, xylitol, soy protein, peanut white, vitamin C, sorbitol, ganoderma lucidum powder, malt powder, coffee powder, bread flour, flour, spices, food additives, raw material powder, medicine intermediates, glass beads, perlite, silicon carbide, silica, activated carbon, epoxy, polyethylene powder, fire extinguishing agents, zircon powder, pigment (phthalocyanine blue, phthalocyanine green and red, phthalocyanine Qinghuang, Huang Dan, fever ceramic pigment), magnetic materials, cobalt powder, pyrophyllite powder, barium sulfate, lithium manganese oxide, iron ash, silica powder, glaze, paint, pollen, dehydrated vegetables, egg powder, milk powder, baking soda, flavor, magnesium oxide, magnesium hydroxide, calcium oxide, silicon nitride, alumina, molybdenum disulfide, cellulose, nano-titanium dioxide, PVC resin powder, barium sulfate, silica powder, melon child bean gum, calcium fluoride powder and many other powder materials.