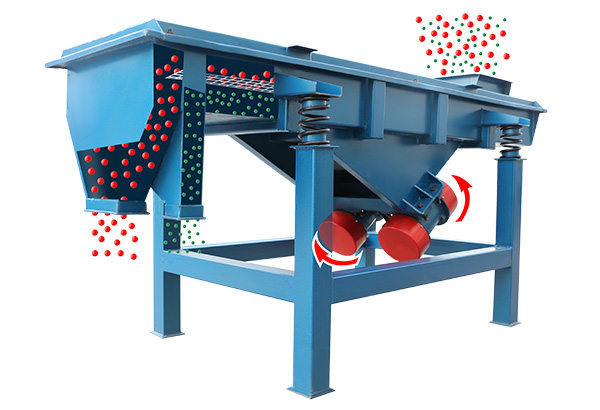

Application

Linear vibrating screen has a unique effect on powdery, granular materials selection and classification. Widely used in chemical, pharmaceutical, food, metal, metallurgy, mining and other industries. 1.Chemical industry: fertilizers, urea, petroleum coke, resins, paints, cosmetics, paints, and so on. 2.Pharmaceutical industry: industrial chemicals, the powder particles pills, pellets, etc. 3.Food industry: soy, chestnut, small steamed bread, spices, sugar, starch, salt, rice flour, milk powder, soy milk, egg, soy sauce, fruit juice. 4.Metals, mining metallurgy: aluminum powder, lead powder, copper powder, ore alloy powder, powder electrodes, quartz sand. 5.Other industries: plastics, abrasives, activated carbon, carbon, building materials industry.