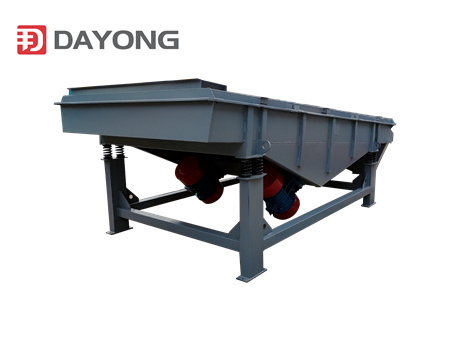

Linear Vibrating Screen For Stone Stock

Quartz sand, machine-made sand, river sand, kaolin, artificial sand and other common sand and gravel materials in various fields such as building materials and ceramics have clear grain size specifications and use regulations. However, this kind of sand and gravel not only has high precision requirements, but also rejects the mining vibrating screen. The production demand is still large, and the rotary vibrating screen cannot meet the requirements. At this time, the linear vibrating screen can play the biggest role - the output precision is correct.

View More+