A metal powder formed by partial or complete alloying of two or more components. Alloy powders are mainly classified according to their composition, including iron alloy powder, copper alloy powder, nickel alloy powder, cobalt alloy powder, aluminum alloy powder, titanium alloy powder, and precious metal alloy powder.

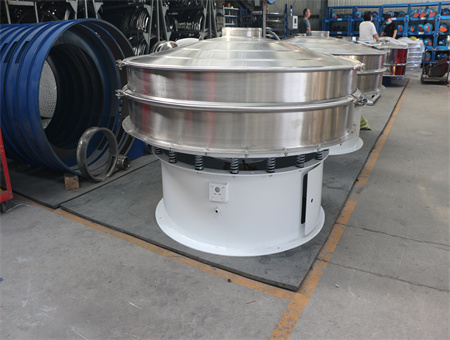

The screening and impurity removal of alloy powder cannot be separated from the use of

rotary vibrating screens.

The power after basic rotary motion is similar to manual screening, the eccentricity is adjustable from 25 to 40mm, and the low speed V-belt drive is adjustable from 120 to 360rpm The residence time of each product can be adjusted towards the drive axis by the radial and cutting angles of the rolling screen Thereforee, a three dimensional tumbling motion for leveling and throwing is established Carborundum is uniformly dispersed on the entire screen surface from the center to the outer edge, there propagating axially in a spiral motion The fine particles that complete the entire screening process The horizontal and vertical accelerations increase with the movement of the particles, and the silicon carbide close to the mesh size is successfully separated; The larger particles are transported to the outlet, and the flow is controlled by an adjustable guide device, which is an Another factor that controls the residence time of emergency This process is repeated between each screen layer

Dayong Company is a manufacturer specializing in the design, development, manufacture of screening, conveying and other mechanical equipment It has a material technical research and development team, focusing on providing customers with professional customized products and differentiated services according to their actual needs

.jpg)