Background description:

A building materials manufacturer needs to screen sand to obtain fine sand that meets the requirements for concrete production. The customer's output requirement is 6 tons per hour and the mesh size is 1.5mm. In order to meet the needs of our customers, we recommend the use of a combination of linear screens and inclined screw conveyors.

solution:

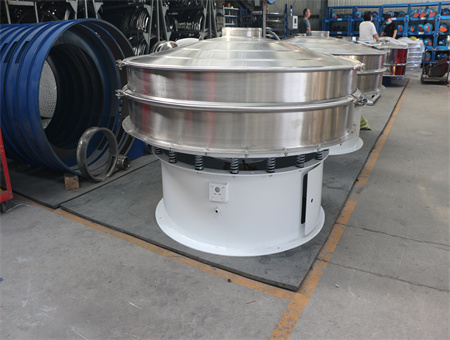

Linear screen: Model

1020 linear screen is used as screening equipment. This screening machine has a large screening area and high processing capacity, and can meet the output requirement of 6 tons per hour. The screen and grid are made of stainless steel 304 to ensure corrosion resistance and long service life. The linear screen divides the sand into different particle sizes through vibrating screening to meet the requirement of a mesh size of 1.5mm.

Inclined screw conveyor: Choose an inclined screw conveyor with a pipe diameter of 219mm, which is made of carbon steel as a whole. The inclined screw conveyor can transport sand from the feed port of the screw conveyor to the feed port of the linear screen to achieve a continuous screening process. The inclined screw conveyor has an adjustable inclination angle and can be adjusted according to actual needs to better suit the production site.