A

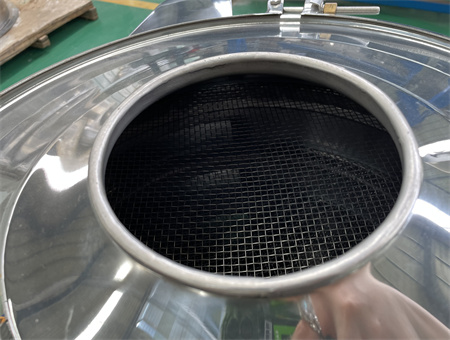

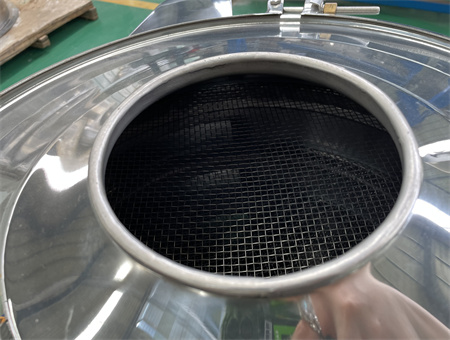

rotary vibrating screen is a simple machine that can be incorporated into various processes for the separation of materials. In the case of corn starch, the vibrating screen works with a mesh to separate the starch from the rest of the substance. The rotary vibrating screen consists of a motor that creates vibration, a feed spout that allows the material to enter the screen, and an outlet for the separated starch.

The application of the

rotary vibro sieve for corn starch is prevalent in the food industry, particularly in the production of bakery products, dairy, and beverages. The use of this equipment is critical in ensuring that the corn starch used in food is sterilized and free of unwanted impurities. The rotary vibrating screen for corn starch is also beneficial in the pharmaceutical industry, where it can be used in the processing of medicine.

The benefits of utilizing a rotary vibrating screen for corn starch are immense. One of the advantages is that the equipment is user-friendly, and its design is simple and easy to maintain. The rotary vibrating screen is also cost-effective, allowing manufacturers to reduce their production expenses and redirect the funds to other important areas of their business.

Another benefit of the rotary vibrating screen for corn starch is that it reduces the risk of cross-contamination. Since this equipment is designed to separate materials, it ensures that the corn starch is free of contaminants that can negatively impact the quality of the final product. Consequently, the rotary vibrating screen minimizes the risk of product recalls and improves the reputation of the manufacturer.

In conclusion, the rotary vibrating screen for corn starch is an essential piece of equipment in the food industry. This machine ensures that corn starch is free of unwanted impurities and maintains its purity during the production process. The rotary vibrating screen is user-friendly, cost-effective, and reduces the risk of product recalls and cross-contamination. Manufacturers who utilize this equipment can deliver high-quality products that meet the expectations of their customers.

.jpg)