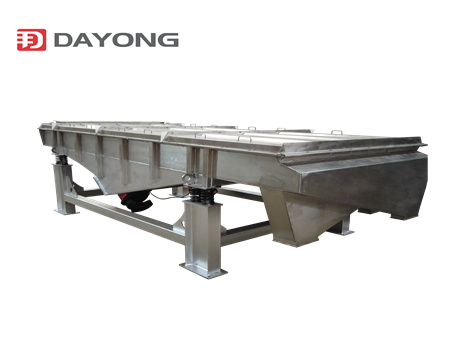

The standard model

linear vibrating screen with a mesh capacity of 2-400 mesh can achieve a maximum output of 20 tons/hour. The 1-6 layer detachable screen box design can classify stones in 2-7 types, and the number of layers of the screen box can be changed according to screening needs.

Take quartz sand as an example. When it is used as a cement formula, abrasive, water purification material, the required particle size is different. Its processing and production need to go through the following processes: primary crushing - re crushing - screening - fine crushing - re screening - sand making - sand washing. The role of the screening machine in this process cannot be underestimated. It can intercept the sand and stone materials that do not meet the next processing requirements after each crushing process, Crush the unqualified sand and stone materials again.

The

linear vibrating screen can remove impurities or grade quartz sand, intercept the large particles of quartz sand at the top layer, and continue screening the quartz sand that meets the requirements, which can not only achieve uniform screening particle size for each layer, but also intercept and crush the large particles of quartz sand and stone again. The same applies to machine made sand, river sand, artificial sand, etc.

Therefore, whether facing sand and gravel materials or soil resources, linear vibrating screens can play a good role. The inlet and outlet can be connected to other equipment, which means that linear vibrating screens can achieve automation of screening and greatly save labor costs. At the same time, its sealing design also avoids the scattering of stone dust during the screening process, undoubtedly improving the production site conditions.

.jpg)

.jpg)