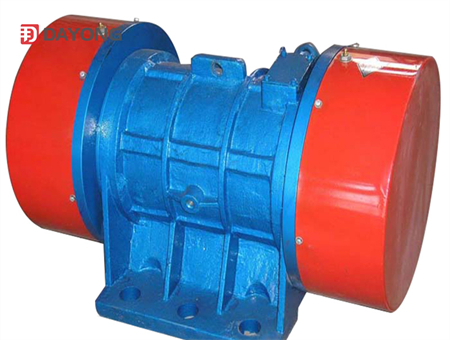

Working principle of horizontal motor

Horizontal vibration motor is a common vibration equipment, widely used in chemical industry, metallurgy, mining and construction industries. It uses a combination of asymmetrical weight fit and opposite steering to achieve vibration, and can control the vibration amplitude and frequency by adjusting the weight and rotational speed.

View More+

.jpg)

.jpg)