Square gyratory screen is a new multi-purpose high-efficiency screening equipment, usually suitable for cement, fertilizer, paper or food industries, suitable for various dry and wet screening industries related to granules and powder granules. The structure design of the equipment is very ingenious. The entire screening process is almost close to manual screening. It can combine the plane circular motion of the screen and the upward parabolic motion of the bump, and then adjust the meridional and tangential angles. , So as to change the time and movement route of the material staying on the screen surface, and finally achieve a better screening effect, so the device is an effective principle that simulates the manual screening movement, its screening accuracy, efficiency and screen mesh The service life is 5-10 times that of conventional round screens.

Advantages

1.The equipment uses a fully enclosed structure, the dust is not flying and can reduce the noise during operation to a very low level, which meets the requirements of environmental protection.

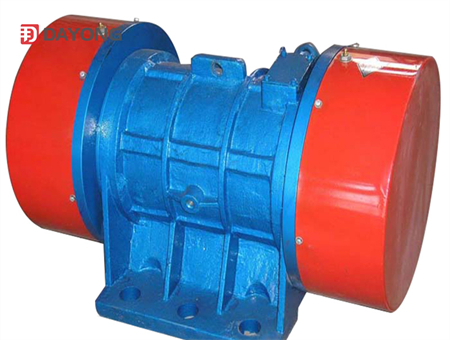

2. Vibration motor adopts imported ordinary motor as the transmission source, German technology is introduced, and the transmission mode imitates manual screening.

3. The square swing sieve adopts a gentle swing form for sieving, which can effectively protect the original state of the material particles from being damaged, and is particularly suitable for flammable, explosive and static materials, such as wool materials.

4. Combining three motion modes of circle, ellipse and straight line, the screening effect is good, suitable for screening of multiple materials, the screening accuracy is high, multi-layer screening and classification can be used for removing impurities, and can meet different customer requirements.

5. The use of advanced steel wire hanging structure ensures that the operation of the equipment is more balanced.

6. The equipment is equipped with an automatic tensioning and automatic cleaning screen installation system to make the screen utilization rate higher and longer life. The process of replacing the screen is simpler and faster.

Working Principle

The screen surface of the square swing screen is horizontally or slightly inclined, and the general inclination angle is between 0 and 5 degrees. When the screen machine is normally started, the screen box will move back and forth under the action of inertial force, and The screen surface is driven to swing periodically, and the materials are uniformly dispersed on the entire screen surface from the center to the outer edge, making a plane gyroscopic movement, so that the material smaller than the screen surface aperture falls through the screen hole and is successfully separated and discharged. The larger particles of material are continuously rolled in a jumping motion and are transported to the outlet. The outlet is an adjustable guide device that can effectively control the flow rate of the material and the residence time of the material on the screen surface. Thus completing the screening work.

(1).jpg)