Efficient screening solution to meet German customers’ requirements for pea classification

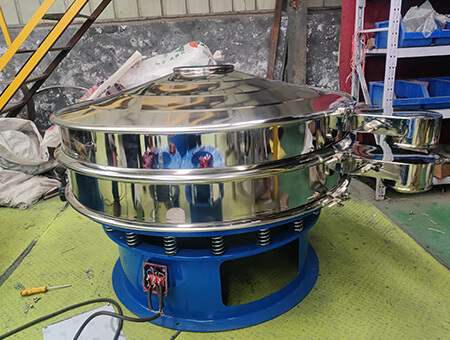

In order to meet the requirements of German customers for pea grading, we offer you an efficient screening solution. We recommend using a rotary vibrating screen with three layers in diameter, equipped with woven meshes with apertures of 9mm, 7mm and 5mm. The parts in contact with the material are made of 304 stainless steel.

View More+