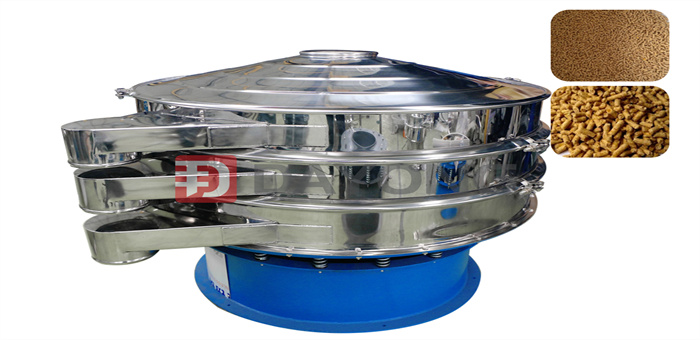

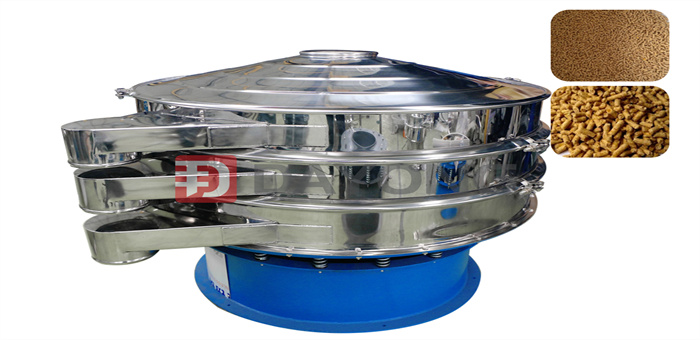

This case involves a feed production company who encountered the problem of uneven particle sizes in raw materials, resulting in unstable feed quality. In order to solve this problem, they chose a 1500mm rotating vibrating screen and equipped it with a 40-mesh screen.

The

1500mm rotary vibrating screen is an efficient screening equipment that can screen and separate raw materials through rotational motion and vibration force. The use of 40-mesh screen can effectively separate fine particles and impurities, improving the quality and uniformity of feed.

By using a 1500mm rotary vibrating screen and a 40-mesh screen, the company has achieved remarkable results. First, the screening efficiency is significantly improved, and fine particles are accurately separated, ensuring the quality and uniformity of the feed. Secondly, the rotary vibrating screen has a compact structure, takes up little space, and has strong adaptability. It can be integrated with the production line to improve production efficiency.

In addition, the 1500mm rotating vibrating screen is made of stainless steel contact parts, which meets hygienic requirements and is relatively simple to clean and maintain, reducing production line downtime and maintenance costs.

We can see the important role of using 40 mesh screen and 1500mm rotating vibrating screen in feed screening. We will continue to develop and produce high-quality screening equipment to provide more solutions and technical support for feed production companies.