Working Principle Of Vibrating Sifter Machine/vibrating powder screen machine/sieving machine powder/sieve vibrator

Working Principle Of Vibrating Sifter Machine/vibrating powder screen machine produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. is dedicated to screening food powder.It only takes 3 to 5 minutes to replace the screen of the corresponding size. In order to improve the screening effect of the rotating vibrating screen when screening fine materials, an ultrasonic system and other equipment can be added.

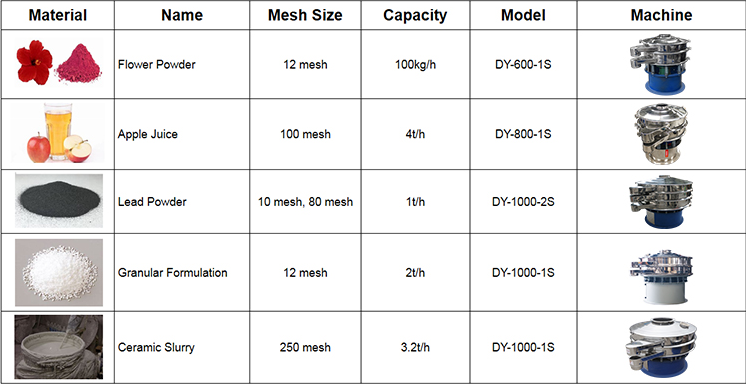

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

Working Principle Of Vibrating Sifter Machine/vibrating powder screen machine is designed for accurate classification and grading. One operation can take up to 5 minutes, low noise and high efficiency. It only takes 3 to 5 minutes to change the network. It is used for powder screening and liquid screening.

The screening work of rotary vibrating screen is mainly due to the eccentric weights at the upper and lower ends of the motor. The included angles of the eccentric weights at the upper and lower ends are different, the motion trajectories are different, and the screening effect is also different. The angle can be adjusted according to the food powder.The grid of the rotating vibrating screen will not be blocked, it can be screened to 500 mesh or 0.028mm, and the coarse and waste materials can be discharged automatically. Can work continuously.