Why does the linear vibrating screen not feed?

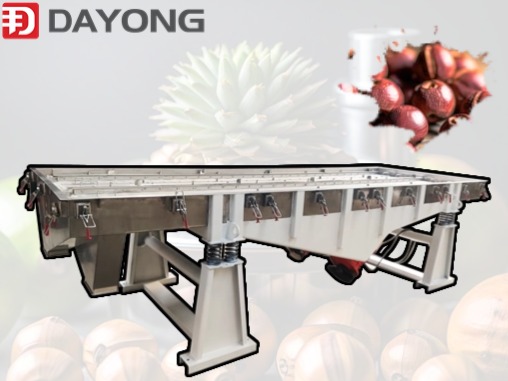

The linear vibrating screen has a high-yield screening mechanical screening equipment, which is an indispensable machine in the production and processing of various industries. Some users reported that why my vibrating screen does not feed? Next, Dayong Vibrating Equipment Co., Ltd., which has many years of vibrating screen production experience, will answer for you.

Reasons why the linear vibrating screen does not feed:

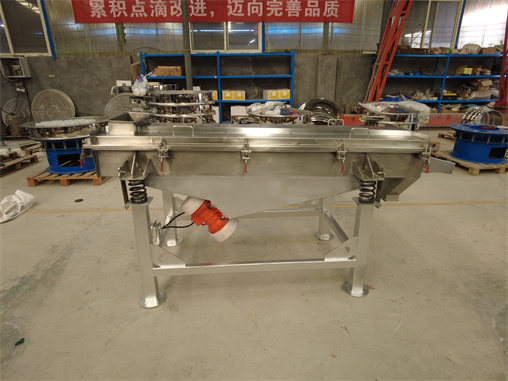

1. The steering problem of the vibrating motor: Two horizontal vibrating motors are used as the vibrating screen when the linear screen is used. When the user connects the positive and negative poles wrongly, it will cause the motor to rotate in the same direction, and there will be a problem that the material on the screen surface will not go out;

2. The installation position of the motor: There are three installation positions of the vibrating motor of the linear screen, namely the bottom, both sides and the upper part. If the vibrating motor is installed close to the feed inlet, the material on the screen surface will slow down after running for a certain distance and finally stay on the screen surface;

3. The height of the discharge port is higher than the screen surface: when designing a linear screen, if the discharge port is higher than the screen surface, the problem of material stagnation on the screen surface will occur during the production process.