Why are ultrasonic vibrating screens often used to screen powders?

Fine powdered products require impurity removal and sieving during processing to achieve high-quality requirements. This requires the use of ultrasonic vibrating screens to achieve.

- Why should you choose an ultrasonic vibrating screen?

①The ultrasonic vibrating screen has a unique screen cleaning device, which can effectively solve the phenomenon of static electricity and agglomeration of materials, and has a good screening effect for ultra-fine materials.

②Compared with ordinary vibrating screens, the accuracy of ultrasonic vibrating screens can be increased by 1%-100%, and the output can be increased by 1-8 times.

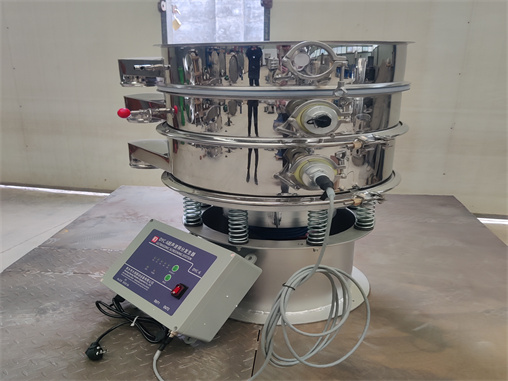

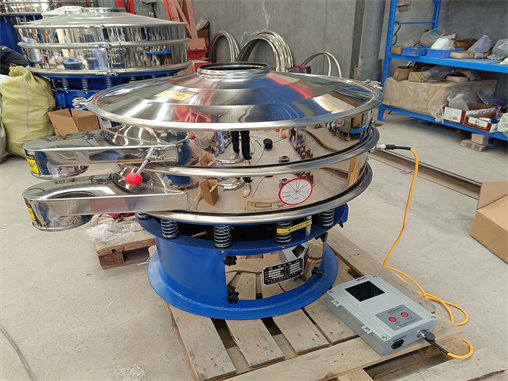

③The ultrasonic vibrating screen is made of stainless steel, which is clean and hygienic.And after polishing, it can achieve no black spots, no burrs, and smooth effect.

- How does an ultrasonic vibrating screen work?

The ultrasonic vibrating sieve is to combine the ultrasonic generator with the vibrating screen to improve the electrical energy, and then use the ultrasonic oscillator head to convert the high-frequency electrical energy into mechanical energy, so that the screen surface produces supersonic vibration that cannot be seen by the naked eye.The ultra-fine powder receives a huge ultrasonic acceleration, and the material on the sieve surface always remains suspended, making the screening of ultra-fine powder easy.