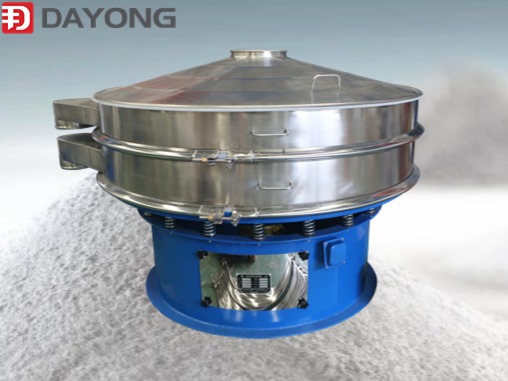

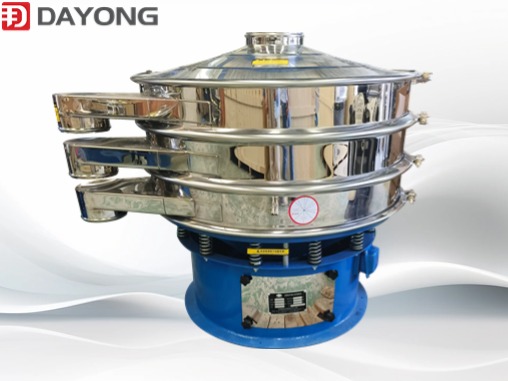

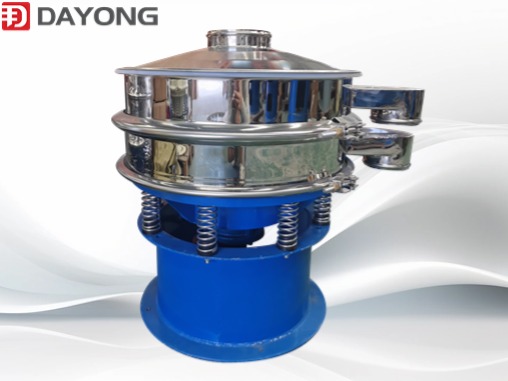

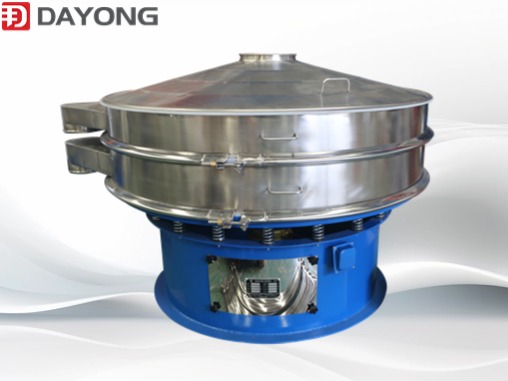

Vibration Sfter Machine For Copper Powder

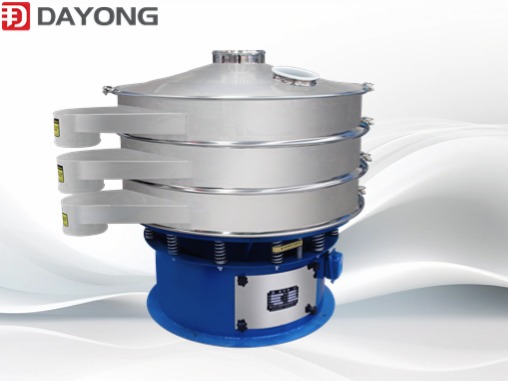

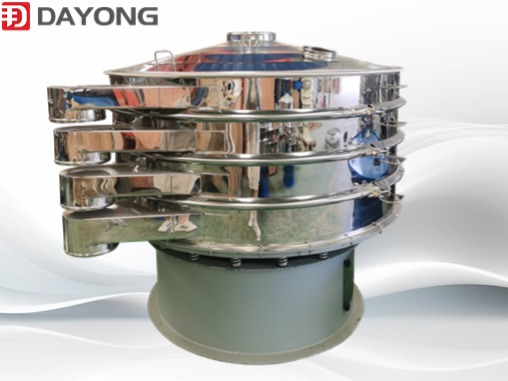

The rotary vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It takes 3-5 minutes to change the screen quickly. The rotary vibrating screen uses a vertical motor as the excitation source. The upper and lower ends of the motor are installed with eccentric weights, which convert the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined, and then transmit this motion to the screen surface. . Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface.

The basic rotary motion is similar to manual screening, the eccentricity is adjustable from 25 to 40mm, The residence time of each product can be adjusted towards the drive axis by the radial and cutting angles of the rocking screen. Therefore, a three-dimensional tumbling motion for leveling and throwing is established. Carborundum is uniformly dispersed on the entire screen surface from the center to the outer edge, thereby propagating axially in a spiral motion. The fine particles thus complete the entire screening process. The horizontal and vertical accelerations increase with the movement of the particles, and the silicon carbide close to the mesh size is successfully separated; the larger particles are transported to the outlet, and the flow is controlled by an adjustable guide device, which is a Another factor that controls the residence time of emery. This process is repeated between each screen layer.

Vibrating screens usually rely on mechanical vibration to classify various minerals in solid state and separate solid liquids. Generally, they are composed of vibrators, screen boxes, support or suspension devices, and transmission devices. Depending on the properties of the processed materials, the structure and performance of the vibrating screen vary greatly. While increasing the vibration intensity to improve the screening efficiency, how to ensure the reliability of the vibrating screen is a major problem in the design and manufacture of the vibrating screen. Large-scale high-end vibrating screens involve many disciplines and complex production processes. They are one of the important machinery in coal, chemical, food, mining and other industries.