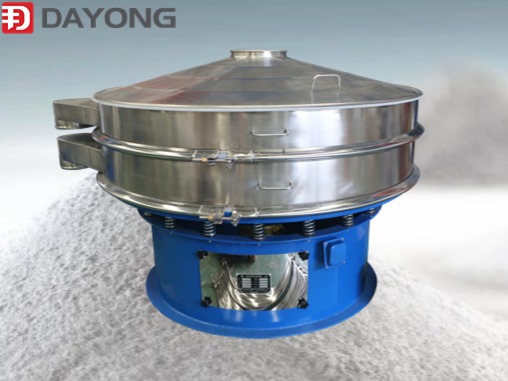

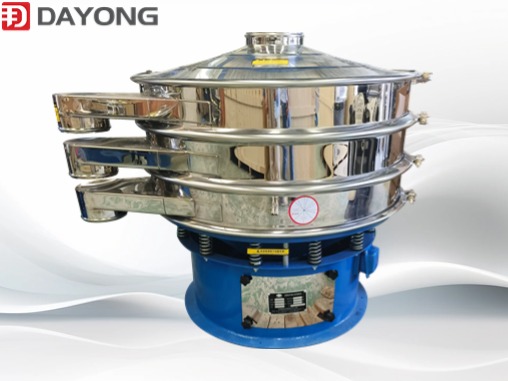

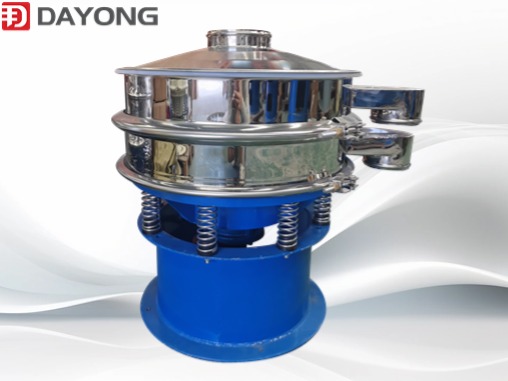

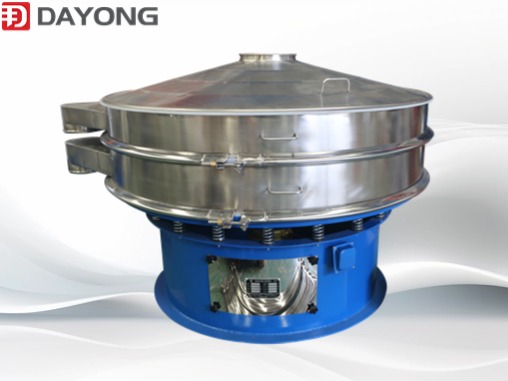

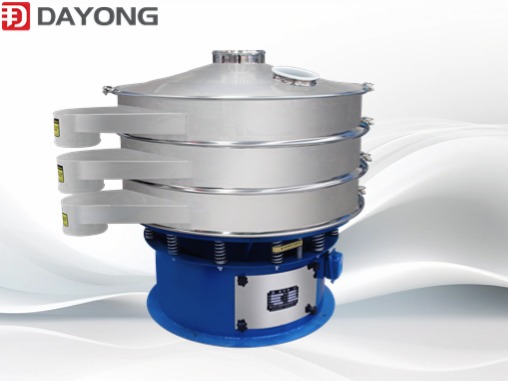

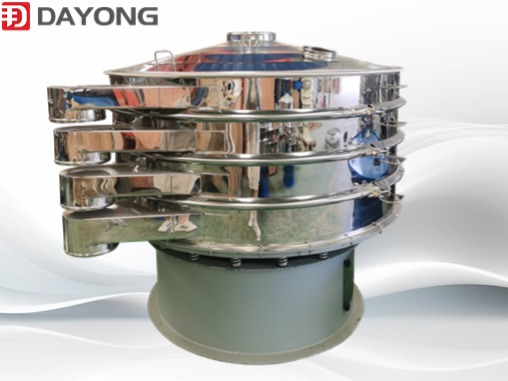

Vibrating Filter Screen Machine For Powder Coating

The rotary vibrating screen controls the movement track of the material on the screen by adjusting the angle of the two eccentric blocks. It uses a vertical motor as the vibration source, and the circular vibrating screen is made of stainless steel 304, and other materials can also be used. The external eccentric block exciter of the circular vibrating screen has the advantages of large exciting force, light weight and small bearing capacity. The side plate of the circular vibrating screen is made of full steel plate without welding, which has high strength and long service life. The beam and the side plate are connected by high-strength bolts without welding. The beams are easy to replace.

The vibrating sieve has the advantages of wide application range, high efficiency, large processing capacity and long life. It is widely used in chemical industry, construction, papermaking, food, mining, ceramics and other industries. The work of circular vibrating screen relies on the inertial force generated by inertial motors and eccentric plates. . It is a single-axis circular motion inertial vibrating screen. Eccentric hammer, considered as the source of vibration. Under the action of the vibrating body, the eccentric hammer can convert the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined. The material of a certain particle size is transported to the screen to achieve the purpose of screening, and the products can be continuously and accurately separated and screened. The multi-layer use can screen out five groups of products with different particle sizes without inconsistent particle sizes. The parts in contact with the raw materials are made of stainless steel, and the screening will be safer and more efficient.