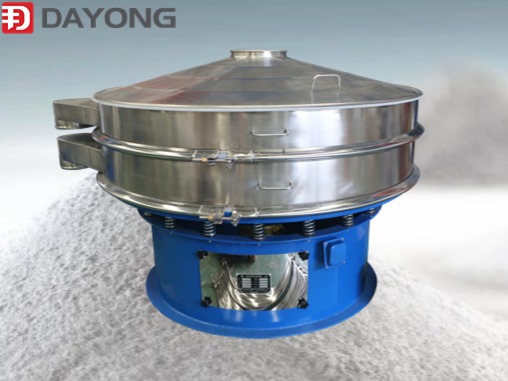

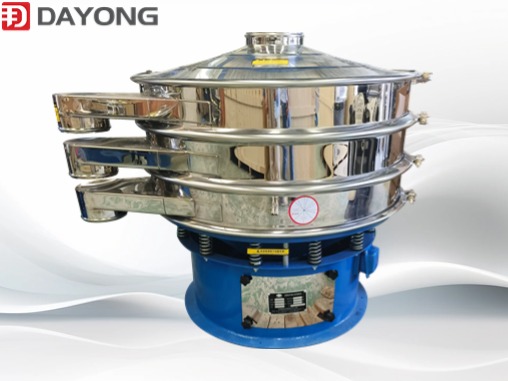

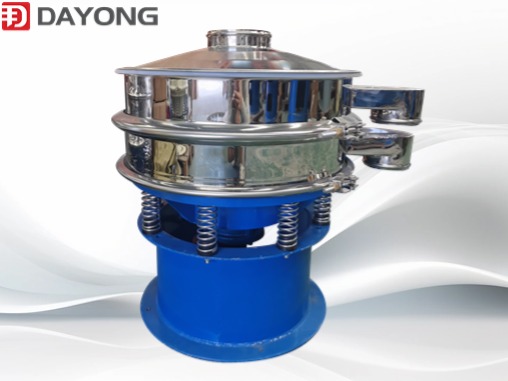

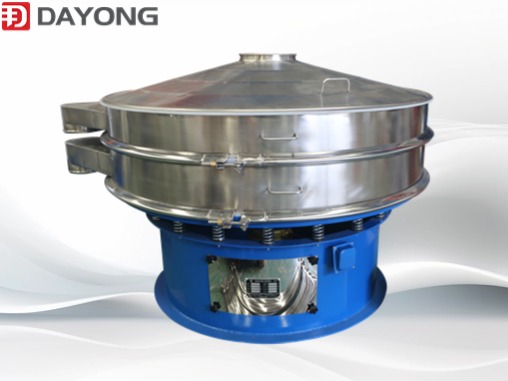

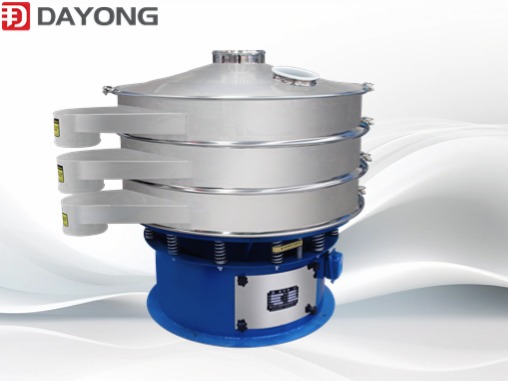

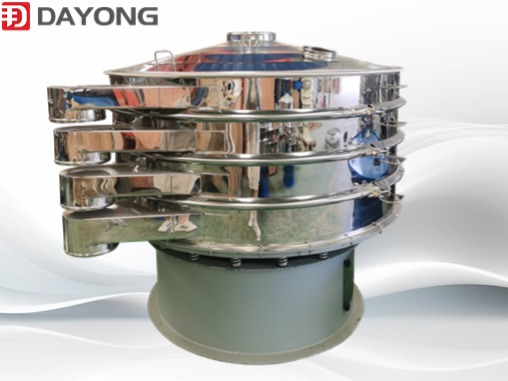

Use and maintenance of vibrating screen

The use and maintenance of DY rotary vibrating screen

1. This machine should be equipped with electrical protection devices.

2. In the early stage of the machine’s operation, check the anchor bolts at least once a day.

3. When the rotation direction of the motor does not meet the requirements, adjust the phase sequence of the power supply.

4. The motor should be well lubricated. Lithium-based grease (ZL-3) should be added every two weeks or so. When refueling, add an appropriate amount of lithium-based grease through the oil cup. When using sealed bearings, the motor does not have an oil cup installed.

5. After the machine has been running for 1500 hours, the bearing should be checked and replaced immediately if there is serious damage.

6. When the machine is used again after being stopped for a long time, the insulation resistance should be measured, which should be greater than 0.5 megohm for the measurement of a 500-volt megger.

The use and maintenance of DY rotary vibrating screen

1. This machine should be equipped with electrical protection devices.

2. In the early stage of the machine’s operation, check the anchor bolts at least once a day to prevent loosening.

3. When the rotation direction of the motor does not meet the requirements, adjust the phase sequence of the power supply.

4. The motor should be well lubricated, and lithium-based grease (ZL-3) should be replenished every two weeks or so. When refueling, add an appropriate amount of lithium-based grease through the oil cup. When using sealed bearings, the motor does not have an oil cup installed.

5. After the machine has been running for 1500 hours, the bearing should be checked and replaced immediately if there is serious damage.

6. When the machine is used again after being stopped for a long time, the insulation resistance should be measured, and it should be greater than 0.5 megohm for the measurement of 500V megohmmeter.

daily maintenance

1. Before starting:

(1) Check whether the coarse mesh and fine mesh are damaged

(2) Whether each set of lashing rings is locked

2. When starting:

(1) Pay attention to whether there is any abnormal noise

(2) Is the current stable

(3) Whether the vibration is abnormal

3. After use: clean up after each use.

Regular maintenance

Regularly check whether the coarse net, fine net and spring are fatigued and damaged, whether each part of the fuselage is damaged due to vibration, and the parts that need to be lubricated must be lubricated.