ultrasonic vibrating screen in spice screening

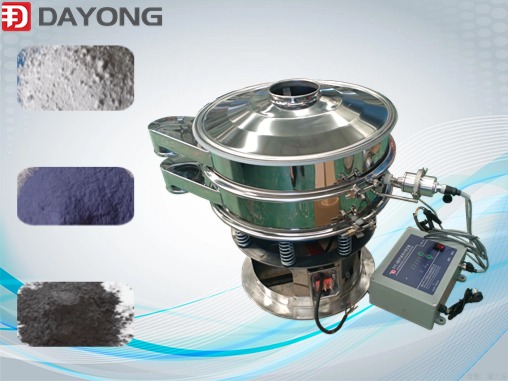

The screening process is crucial in spice production. The DY-1200 ultrasonic vibrating screen from Xinxiang Dayong Vibration Equipment Co., Ltd. accurately screens and prevents blockages. High frequency vibration combined with ultrasonic waves improves screening efficiency and ensures uniform particle size. The device has a simple structure, easy operation, and low maintenance costs.

Screening is a crucial step in the production process of spices. However, due to the small size and viscosity of spice particles, traditional screening equipment often faces the problem of clogging. In order to solve this problem, the ultrasonic vibrating screen of Xinxiang Dayong Vibration Equipment Co., Ltd. has been successfully applied in multiple spice production enterprises.

Recently, a spice manufacturer chose the DY-1200 ultrasonic vibrating sieve. The device has a diameter of 1.2 meters and is equipped with a 40 mesh screen. It can accurately screen out spice particles of the desired size. And it can effectively solve the problem of spice clogging.

In practical applications, ultrasonic vibro sifters have a combination of high-frequency vibration and ultrasonic waves. The spice particles on the sieve are subjected to strong vibrations and impact forces. This effectively prevents particles from adhering and clogging on the sieve. This not only greatly improves the screening efficiency, but also ensures that the screened spice particles have uniform particle size, meeting customers’ high-quality requirements.

In addition, ultrasonic vibrating screens have the advantages of simple structure, easy operation, and low maintenance costs, saving customers a lot of manpower, material resources, and financial resources. The customer is highly satisfied with the performance of the equipment and plans to continue purchasing ultrasonic vibrating screens from Xinxiang Dayong Vibration Equipment Co., Ltd. when expanding production scale in the future.