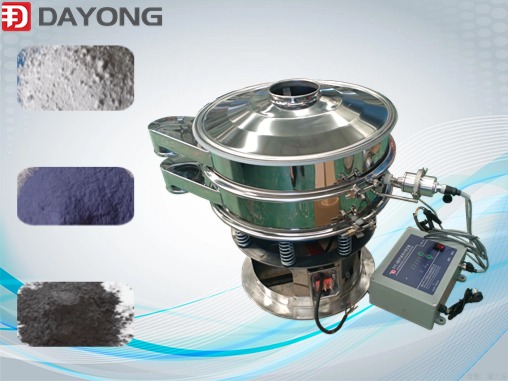

Ultrasonic vibrating screen for screening matcha powder

By sieving through an ultrasonic vibrating screen, impurities in matcha can be removed, making the matcha powder more delicate. The rotary vibrating screen produced by Xinxiang Dayong Vibration Equipment Co., Ltd. has many advantages.

Ultrasonic vibrating screens are widely used in the screening process of matcha powder production lines. Through the screening of ultrasonic vibrating sieve, impurities and coarse powder in matcha powder can be removed.This sieving machine can ensure the fineness and uniformity of matcha powder. At the same time, by adjusting the aperture of the sieve, different particle sizes of matcha powder can be obtained to meet different quality and taste requirements. A matcha factory approached us and purchased the DYC-800 ultrasonic vibrating screen (60 mesh, 80 mesh, 100 mesh) .

The advantages of the ultrasonic vibro sifter produced by Xinxiang Dayong Vibration Equipment Co., Ltd. are:

Using ultrasonic for screen cleaning can effectively solve the problems of static electricity and agglomeration in matcha;

Effectively solving the problem of difficult screening of ultrafine particle materials, with good screening effects for ultrafine particle materials;

Improved the efficiency, accuracy, and output of material screening.

Ultrasonic vibrating screen also has many advantages such as easy replacement of screen mesh, simple operation, easy cleaning, and convenient movement. Xinxiang Dayong Vibration Machinery Co., Ltd. produces a variety of vibrating screen models that support customization. Welcome to call for consultation!