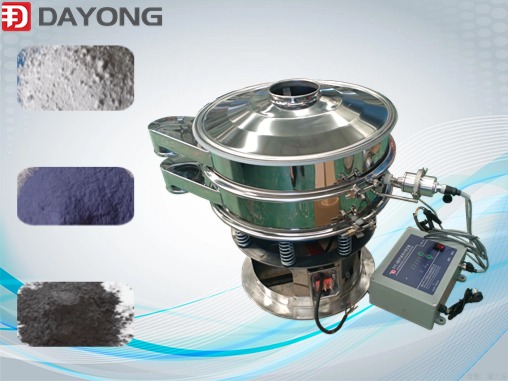

Ultrasonic vibrating screen: fine screening

Xinxiang Dayong’s 800mm double-layer ultrasonic vibrating screen significantly boosts efficiency with low noise and no material clumping. Its design optimizes space and capacity, improving screening quality. Customers report economic benefits, paving the way for future collaboration.

Recently, a company successfully purchased a double-layer ultrasonic vibrating screen with a diameter of 800mm from Xinxiang Dayong Vibration Equipment Co., Ltd. Since it was put into use, the equipment has brought significant efficiency improvement to the company’s production line with its excellent performance.

It is particularly worth mentioning that this ultrasonic vibrating sieve has extremely low noise during operation, which effectively improves the working environment of the workshop, reduces noise pollution to operators, and improves the overall working comfort. Its built-in ultrasonic technology effectively avoids the agglomeration of materials during the screening process, ensuring the dual improvement of screening efficiency and screening quality.

The double-layer design not only optimizes space utilization, but also further improves screening capacity, meeting the company’s urgent need for efficient and stable screening equipment.

Customer feedback shows that this ultrasonic vibrating screen of Xinxiang Dayong Vibration Equipment Co., Ltd. has created considerable economic benefits for the company. This cooperation has undoubtedly laid a solid foundation for the in-depth cooperation between the two parties in the future.