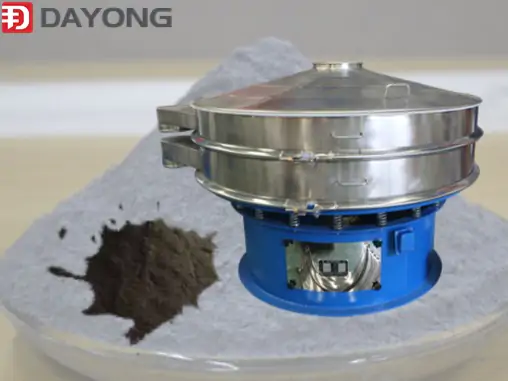

Ultrasonic vibrating screen application range

Ultrasonic rotary vibrating screen is widely used in: 400 mesh, 500 mesh, 600 mesh screening silicon carbide, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, bumet powder, malt powder, coffee powder, Ultrasonic vibrating screen for electromagnetic powder, negative electrode materials, etc

Ultrasonic rotary vibrating screen is widely used in: 400 mesh, 500 mesh, 600 mesh screening silicon carbide, stainless steel powder, tungsten powder, nickel powder, cobalt powder, powder coating, quartz powder, bumet powder, malt powder, coffee powder, Ultrasonic vibrating screen for electromagnetic powder, negative electrode materials, etc.

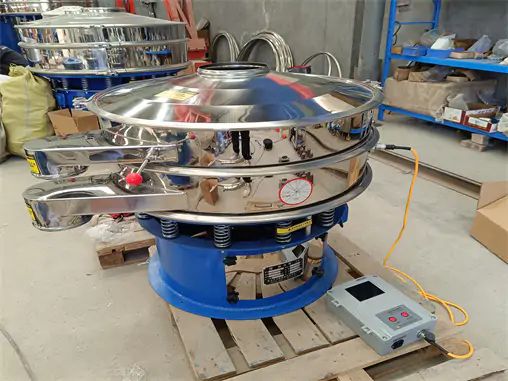

The vibrating screen frame is based on the original motor-driven vibrating screen vibration, and an ultrasonic system is added. It plays a vital role in solving the problem of screen mesh clogging, making the particles that the vibrating screen can screen finer and the screening efficiency higher.

- The ultrasonic vibrating screen can achieve high-precision, high-mesh screening while controlling a narrow particle size range. The screening accuracy can be increased by 1-100%, and the output can be increased by 1-10 times.

- It can be used in single layer or multi-layer to ensure that the original characteristics of the materials being processed remain unchanged.

- Self-cleaning function of the screen: it can screen larger than 500 mesh, without clogging of the mesh, and the screening efficiency will not decrease.

- Really solve the screening problems such as strong adsorption, easy agglomeration, high static electricity, high fineness, high density, and light specific gravity.