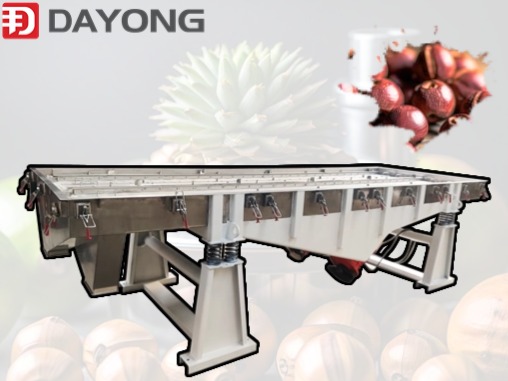

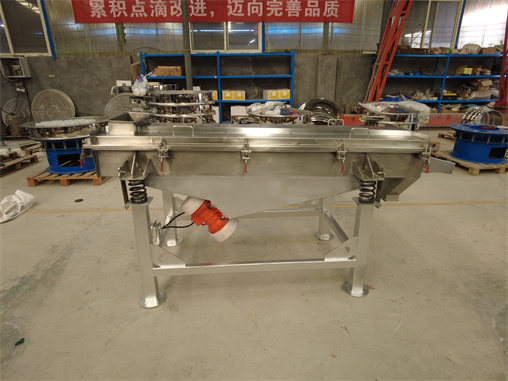

Two Layers Linear Vibrating Screen For Black Soldier Fly Larvae

The Two Layers Linear Vibrating Screen For Black Soldier Fly Larvae and sold by Xinxiang Dayong Company has a wide range of applications. The linear vibrating screen uses a vibrating motor as the vibration source, and the material rolls while moving in a straight line. The material enters the entrance evenly, and then passes through the screen to produce materials of different sizes, which are discharged from different doors. It is suitable for low consumption, high output, simple structure, convenient maintenance, fully enclosed structure, non-scattering powder.

Linear vibrating screen is mainly composed of eccentric block vibrator, screen box, motor and supporting device. Through the flexible coupling, the motor drives the eccentric mass of the vibrator at high speed, generating centrifugal force. Then, the material in the inclined screen surface is continuously cast by the force generated by the screen box to achieve the purpose of classification.

The Two Layers Linear Vibrating Screen For Black Soldier Fly Larvae and sold by Xinxiang Dayong Company has a wide range of applications. The linear vibrating screen uses a vibrating motor as the vibration source, and the material rolls while moving in a straight line. The material enters the entrance evenly, and then passes through the screen to produce materials of different sizes, which are discharged from different doors. It is suitable for low consumption, high output, simple structure, convenient maintenance, fully enclosed structure, non-scattering powder.

Linear vibrating screen is mainly composed of eccentric block vibrator, screen box, motor and supporting device. Through the flexible coupling, the motor drives the eccentric mass of the vibrator at high speed, generating centrifugal force. Then, the material in the inclined screen surface is continuously cast by the force generated by the screen box to achieve the purpose of classification.

When the two vibrating motors rotate synchronously and reversely, the eccentric excitation force generated cancels each other in the direction parallel to the motor axis, and the motor shaft superimposes a force in the vertical direction, so the motion trajectory of the screening machine is a straight line. The two motor shafts are inclined relative to the vertical direction of the screen surface. Under the combined action of the exciting force and the material self-weight, the material is thrown or jumped straight forward on the screen surface, so as to achieve the purpose of material screening and classification. The suitable particle size is 0.074-5mm, the water content is less than 7%, and various powder or granular dry sieve non-stick materials. The maximum feed size does not exceed 10mm.