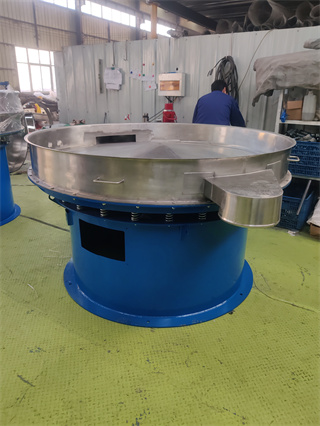

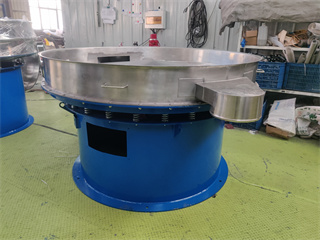

Top Brand Fully Enclosed Frequency Full Stainless Steel Vibrating Sieve Separator Machine/Durable Shaft Rubber Spring Compost Drum Vibrating Screen Machine For Sand Washer

The Top Brand Fully Enclosed Frequency Full Stainless Steel Vibrating Sieve Separator Machine/Durable Shaft Rubber Spring Compost Drum Vibrating Screen Machine For Sand Washer is produced by China Xinxiang Dayong Vibration Equipment Co., Ltd. The vibrating screen has a complete set of equipment operating system. A vibration motor is installed at the bottom of the vibrating screen. The movement of the screen is transformed into a three-dimensional movement of horizontal, vertical and inclined, and then this movement is transmitted to the screen surface to achieve the purpose of screening. Dayong Company is committed to the screening needs of every customer with the highest quality, the lowest price and the best service.

The work of the rotary vibro sieving machine relies on the inertial force generated by the inertial motor and the eccentric plate. Due to the vibration of the screen box, the material is thrown out, and the material of a certain size passes through the screen. The screening purpose is achieved. Since the exciter is installed on the center of gravity of the screen box, the two long axes of the ellipse form the shape of Chinese characters, and the upper part of the long axis of the ellipse at the entrance is in the same direction as the discharge port, which is conducive to the diffusion of materials in the screen box, and the complete working process of the equipment, To achieve high-efficiency screening of materials.

Dayong’s products have a series of advantages. First, the equipment does not occupy space, is convenient to move, simple to operate, and easy to maintain, which saves time and space for production; Long service life and easier replacement. Third, the equipment can be used in single or multi-layer to meet the requirements of different screening specifications for the same material.