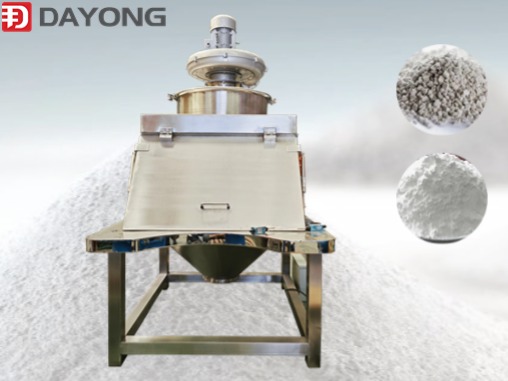

The working principle of round vibrating screen

As a high-precision and fine screening machinery,round vibrating screen is a widely used screening equipment in multiple industries and fields,mainly used for screening,grading, and filtering of powders,particles,and solid materials.The rotary vibration screen is suitable for various fields such as food industry,papermaking industry,metallurgy industry,pharmaceutical industry,chemical industry,ceramics industry,and building materials industry.

The working principle of a round vibrating screen mainly depends on the rotation and vibration motion generated by the vibration source,which includes the following aspects:Vibration source. The vibration source of the rotary vibro sifter is usually provided by a vertical vibration motor,with eccentric weights installed at the upper and lower ends of the motor.This design can convert the rotational motion of the motor into horizontal,vertical, and inclined three-dimensional motion.

Material movement.This motion is then transmitted to the screen surface,causing the material to undergo outward expansion and involute motion on the screen surface,thereby achieving screening.Screening process.During the screening process,coarser materials are screened out first,while finer materials enter the lower layer through the upper sieve and continue to be screened until all materials with suitable particle sizes are screened out.

Adjustment function.By adjusting the phase angle of the eccentric weights at the upper and lower ends,the movement trajectory of the material on the screen surface can be changed,further improving the screening efficiency.