The Material and Difference Of Vibrating Screen/Stainless Steel Rotary Vibro Sieve

Many users usually do not pay too much attention to the material problem when choosing a vibrating screen, so the vibrating screen cannot achieve the ideal screening effect and service life. So what are the differences in the material of the vibrating screen? What are the advantages?

1: Application of rotary vibrating screen made of carbon steel

2: Application of rotary vibrating screen made of stainless steel

The material style of stainless steel vibrating screen is divided into two types: stainless steel and all stainless steel vibrating screen for the contact material parts.

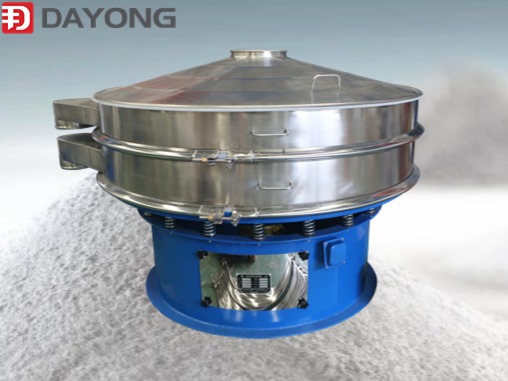

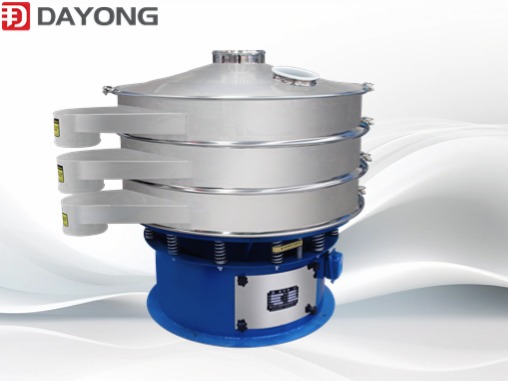

Vibrating screen made of stainless steel

Three: plastic anti-corrosion vibrating screen

Many users usually do not pay too much attention to the material problem when choosing a vibrating screen, so the vibrating screen cannot achieve the ideal screening effect and service life. So what are the differences in the material of the vibrating screen? What are the advantages?

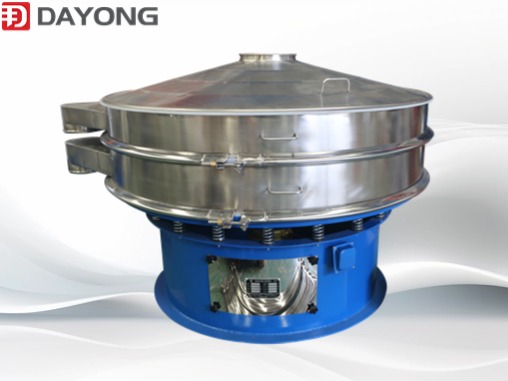

1: Application of rotary sieve made of carbon steel

This is one of the most common rotary vibrating screens. It has no special requirements for the materials to be screened, and is suitable for the screening of some building powder particles. It does not have much strict requirements on the material, but only for the purpose of fine grading, and the style can be designed according to the actual situation on site.

2: Application of rotary vibrating screen made of stainless steel

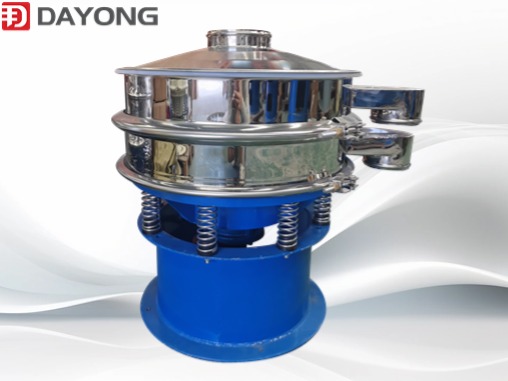

The material style of stainless steel vibrating screen is divided into two types: stainless steel and all stainless steel vibrating screen for the contact material parts.

Vibrating screen made of stainless steel

1) The vibrating screen with the contact material is stainless steel mainly because the material has requirements on the material of the equipment in contact, so as to prevent the material from contacting with carbon steel and contaminating the material, especially in the food industry, white plastic particle industry, etc.

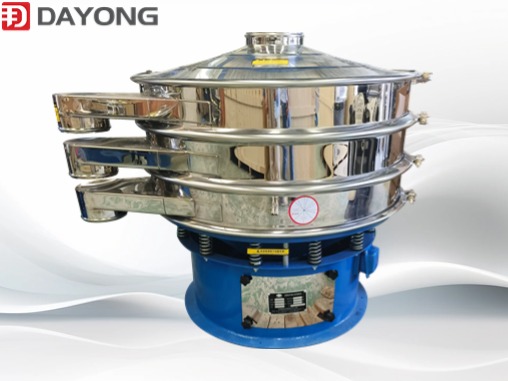

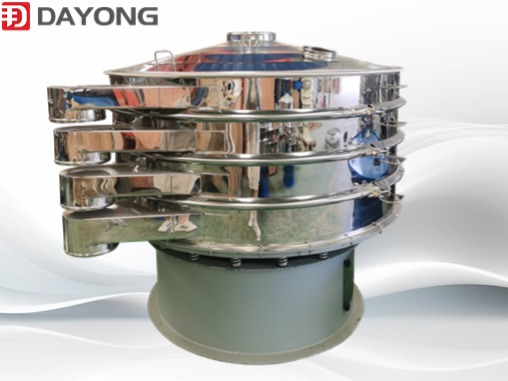

All stainless steel vibrating screen

2) The all-stainless steel vibrating screen is mainly used in food, medicine, chemical and other industries, and its use environment is strict, and it is easy to clean the equipment.

Three: plastic anti-corrosion vibrating screen

The plastic anti-corrosion vibrating screen is mainly used to solve the problems of chemical reaction and strong corrosion caused by contact between special materials and metals during screening. The parts of the rotary vibrating screen in contact with the material are completely made of non-metallic materials from the screen frame, screen mesh, middle frame, sealing cover and screen cleaning device, which completely eliminates the problem that some special materials will have chemical reactions when they come into contact with metal. This machine is suitable for the screening and filtration of dry powder or slurry materials in chemical enterprises, military enterprises and special industries.

If you have other questions about the product, please contact with us.