Talc powder screening – ultrasonic vibrating screen

Ultrasonic vibrating screen screening of talc powder has many advantages. This article will introduce it to you. Xinxiang Dayong Vibration Equipment Co., Ltd. specializes in producing various screening equipment. Welcome to consult!

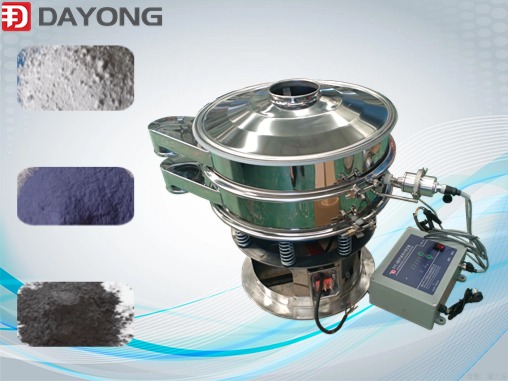

Customer case: Xinxiang Dayong Vibration Equipment Co., Ltd. has a customer. The customer has ordered a double-layer ultrasonic vibrating screen from us. It can screen out three different particle sizes of materials. The material is talcum powder. The equipment material is stainless steel.

Equipment advantages:

1.Efficient screening

The ultrasonic vibrating sieve causes the talc powder particles to form a loose state on the sieve, effectively improving the screening efficiency.

2.Good cleaning effect

Ultrasonic waves can prevent clogging of the sieve and keep it unobstructed. Avoiding the decrease in screening efficiency caused by clogged screens.

3.High screening accuracy

Due to the high screening efficiency and good cleaning effect of ultrasonic vibrating screens, high-precision screening can be achieved.

4.Strong adaptability

Ultrasonic vibrating screen can solve the screening problems of materials with strong adsorption and easy agglomeration by introducing high-frequency vibration waves.

5.Energy conservation and environmental protection

Ultrasonic vibrating screen has low energy consumption, low noise, and minimal pollution. And due to its high screening efficiency and good cleaning effect, it reduces screening time.

The advantages of ultrasonic vibrating screens make them widely applicable and valuable in the field of talc powder screening. The ultrasonic vibrating screen produced by Xinxiang Dayong Vibration Equipment Co., Ltd. can also be customized according to your needs. Welcome to your consultation!