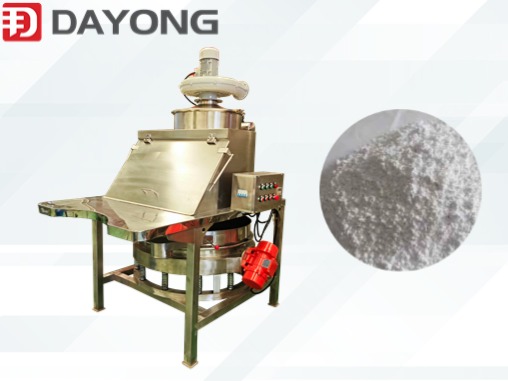

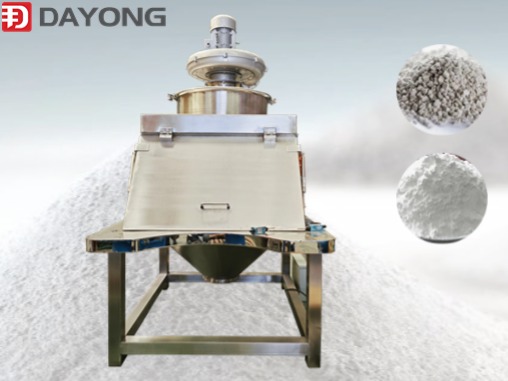

Talc powder feeding and screening production line

Dust free feeding station and rotary vibrating screen are common equipment combinations in material processing. They can work together to achieve dust-free assembly line operations.

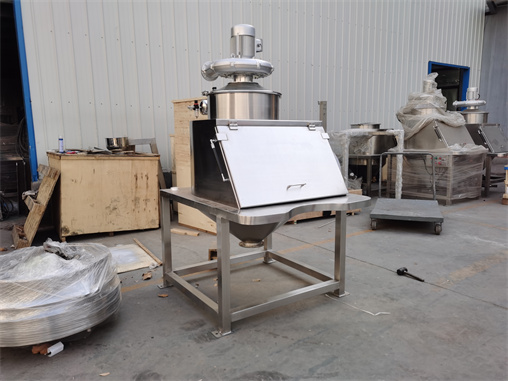

Dust free feeding station and rotary vibrating screen are common equipment combinations in material processing. They can work together to achieve dust-free assembly line operations. Xinxiang Dayong Vibration Equipment Co., Ltd. specializes in producing various screening equipment, feeding stations, loading machines, etc.

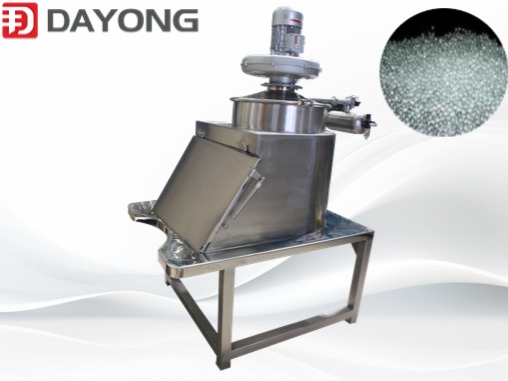

We have a client who wants to screen the feeding of talc powder. Finally, after communication, we selected our dust-free feeder and ultrasonic rotary vibrating screen. Xinxiang Dayong Machinery will provide you with a detailed introduction to the usage steps and advantages.

Usage steps:

- Bag breaking feeding: Manually breaking bags to feed materials into a dust-free feeding station.

- Dust removal: Control the dust-free feeding station and use the upper fan to remove dust. The material falls into the hopper

- Vibration screen screening: Materials are screened and classified according to particle size.

- Material collection: Collect materials according to requirements.

(It should be noted that regular maintenance and cleaning of equipment should be carried out on a daily basis.)

Advantages: 1. The dust-free feeding station solves the problem of dust dispersion; 2. Achieving continuous production and improving production efficiency; 3. Low noise, low energy consumption, and simple operation; 4. Made of stainless steel material, it will not cause secondary pollution to the material.

Xinxiang Dayong Vibration Machinery Co., Ltd. is a professional source factory that produces feeding machines, vibrating screens, crushers and other equipment. If you have further needs, please feel free to contact us!