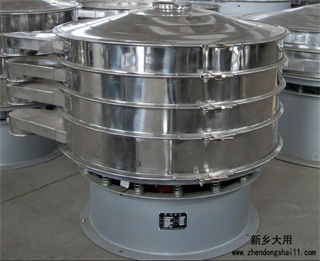

Stone Sand Vibrator Screen Granula Vibratory Screen Circular

High screening accuracy and high efficiency; no dead corners in parts, easy to thoroughly clean and disinfect; new mesh structure, long service life of the screen, only 3-5 minutes to change the screen; single-layer multi-layer screen can be used; small size does not occupy Space, easy to move, the outlet can be adjusted 360 degrees; all parts in contact with the material are made of stainless steel.

High screening accuracy and high efficiency; no dead corners in parts, easy to thoroughly clean and disinfect; new mesh structure, long service life of the screen, only 3-5 minutes to change the screen; single-layer multi-layer screen can be used; small size does not occupy Space, easy to move, the outlet can be adjusted 360 degrees; all parts in contact with the material are made of stainless steel.

The circular vibrating screen powder machine generates three-dimensional vibration force through two uneven and horizontal heavy hammers, one is installed in the upper part to make the screen move horizontally and circularly, and the other is installed in the lower part, so that the screen mesh has a vertical direction. Movement, these two movements are most used each other to produce three-dimensional movement. The material of this screen machine is put into the upper part from directly above the center of the screen. After screening, the coarse material on the screen is discharged from the outlet. The material is discharged from the lower outlet. The diameter of the screen is generally 0.4 to 0.5 meters, and the number of screens is one to five.