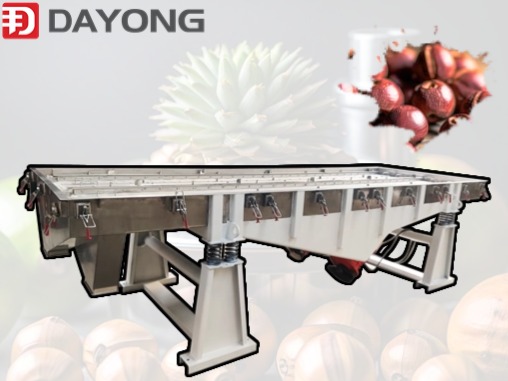

Stainless Steel Vibrating Screen Sieve Machine For Grain/China Low Noise High Quality Rotary Vibrating Screen For Metla Powder Grain Powder /Linear vibrating Screen

Stainless Steel Vibrating Screen Sieve Machine For Grain/China Low Noise High Quality Rotary Vibrating Screen For Metla Powder Grain Powder /Linear vibrating Screen is a new type of high-efficiency screening equipment produced by Xinxiang Dayong Vibration Equipment Company, which is widely used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry and other industries. Linear vibrating screen (linear screen) has the advantages of stability and reliability, low consumption, low noise, long life, stable vibration shape and high screening efficiency.

Stainless Steel Vibrating Screen Sieve Machine For Grain/China Low Noise High Quality Rotary Vibrating Screen For Metla Powder Grain Powder /Linear vibrating Screen is a new type of high-efficiency screening equipment produced by Xinxiang Dayong Vibration Equipment Company, which is widely used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry and other industries. Linear vibrating screen (linear screen) has the advantages of stability and reliability, low consumption, low noise, long life, stable vibration shape and high screening efficiency.

The basic principle is to use the heavy hammer (uneven hemispherical heavy hammer) installed on the upper and lower ends of the motor shaft to convert the rotary motion of the motor into three-dimensional motion of degree, vertical and inclination, and then transmit this motion to the screen surface. It is assumed that changing the phase angle of the upper and lower weights can change the traveling direction of the raw material.

Motor Instructions:

This series of motors can continuously output rated excitation force when the following conditions are met.

Structure and functional description of each part

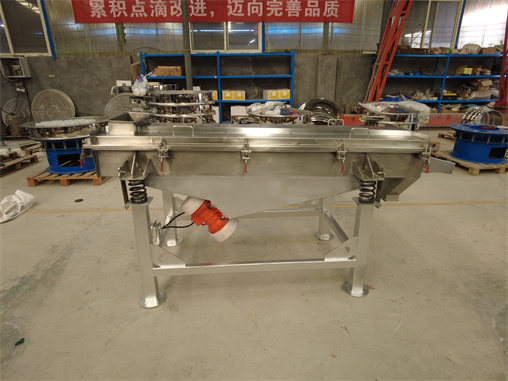

The screen machine is mainly composed of screen box, screen frame, screen mesh, vibration motor, motor pedestal, vibration damping spring, bracket and so on.

1. Screen box: It is welded by several kinds of steel plates with different thicknesses. It has certain strength and rigidity and is the main component of the screen machine.

2. Screen frame: Made of pine or wood with less deformation, it is mainly used to keep the screen flat and achieve normal screening.

3. Screen: There are several kinds of screens such as low carbon steel, brass, bronze, stainless steel wire.

4. Vibration motor (for use and maintenance methods, please refer to the vibration motor instruction manual).

5. Motor pedestal: Install the vibration motor, and the connecting screws must be tightened before use, especially for the trial of the new screen machine

6. Shock-absorbing spring: prevent the vibration from being transmitted to the ground and support the full weight of the screen box. When installing, the spring must be perpendicular to the ground

7. Bracket: It consists of four pillars and two channel steels, which support the screen box. When installing, the pillars must be perpendicular to the ground, and the channel steels below the two pillars should be parallel to each other.