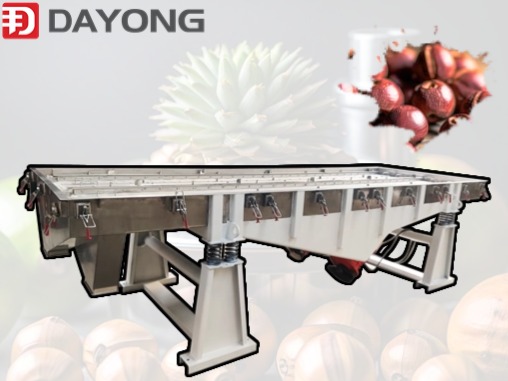

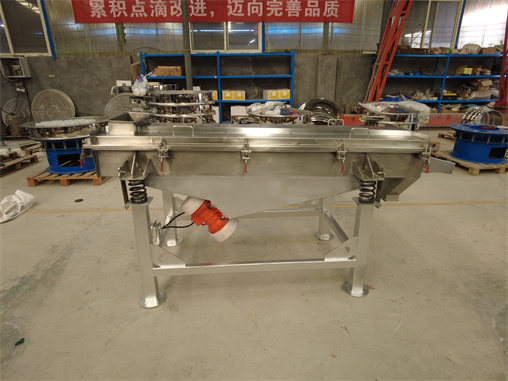

Stainless Steel Linear Sieving Machine/Linear Sieve Machine/Linear Vibrating Screen Dayong/Raw Material Plastic Pellets linear vibrating screen

The motion trajectory of the Stainless Steel Linear Sieving Machine/Linear Sieve Machine/Linear Vibrating Screen Dayong/Raw Material Plastic Pellets linear vibrating screen manufactured by Xinxiang Dayong Vibration Equipment Co., Ltd. is similar to a circle; when the screened material enters the screen surface, the material layer on the screen surface is loosened due to the vibration of the screen surface and jumps away from the screen surface. The granular material can fall through the material layer, while the large particle material cannot penetrate the material layer, so that the original disorganized particle group is separated, forming a regular arrangement of small particles on the bottom and large particles on the top; the fine particles that reach the screen surface , those smaller than the sieve hole will pass through the sieve, and finally realize the separation of coarse and fine particles, and complete the sieving; at the same time, the particles stuck in the sieve hole will be shaken out to ensure that the sieve hole is not blocked.

The motion trajectory of the Stainless Steel Linear Sieving Machine/Linear Sieve Machine/Linear Vibrating Screen Dayong/Raw Material Plastic Pellets linear vibrating screen manufactured by Xinxiang Dayong Vibration Equipment Co., Ltd. is similar to a circle; when the screened material enters the screen surface, the material layer on the screen surface is loosened due to the vibration of the screen surface and jumps away from the screen surface. The granular material can fall through the material layer, while the large particle material cannot penetrate the material layer, so that the original disorganized particle group is separated, forming a regular arrangement of small particles on the bottom and large particles on the top; the fine particles that reach the screen surface , those smaller than the sieve hole will pass through the sieve, and finally realize the separation of coarse and fine particles, and complete the sieving; at the same time, the particles stuck in the sieve hole will be shaken out to ensure that the sieve hole is not blocked.

1. Using tire coupling, flexible connection, stable operation, small impact on the motor

2. The block eccentricity is used as the exciting force, which not only increases the exciting force, but also can be adjusted randomly, which is convenient for modular design and the use of small amplitude, high frequency, large inclination angle structure, high screening efficiency and large processing capacity , long life, low energy consumption, low noise

3. The screen surface material is wear-resistant, fatigue-resistant and corrosion-resistant, and has high opening rate, light weight and high classification accuracy; steel coil springs are used as vibration damping devices, which have reliable performance, long service life and flexibility, and can be changed by changing The inclination of the screen surface can control the processing capacity; the maintenance of the equipment is simple and convenient, and the operation efficiency of the whole machine is obviously improved.

Welcome to consult, the technical staff of Dayong Company will customize the screening plan for you.