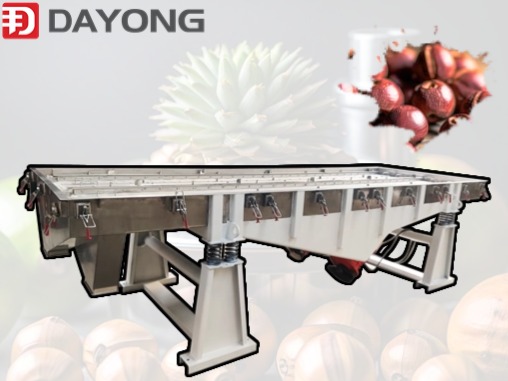

Soybean Linear Vibrating Sieve Machine/Stainless Steel Vibrating Screen Sieve Machine For Grain/Linear Vibrating Screen / Sieve Separation For Grain Material

Soybean Linear Vibrating Sieve Machine/Stainless Steel Vibrating Screen Sieve Machine For Grain/Linear Vibrating Screen / Sieve Separation For Grain Material is a new type of high-efficiency screening equipment produced by Xinxiang Dayong Vibration Equipment Company, which is widely used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry and other industries. Linear vibrating screen (linear screen) has the advantages of stability and reliability, low consumption, low noise, long life, stable vibration shape and high screening efficiency.

Soybean Linear Vibrating Sieve Machine/Stainless Steel Vibrating Screen Sieve Machine For Grain/Linear Vibrating Screen / Sieve Separation For Grain Material is a new type of high-efficiency screening equipment produced by Xinxiang Dayong Vibration Equipment Company, which is widely used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry and other industries. Linear vibrating screen (linear screen) has the advantages of stability and reliability, low consumption, low noise, long life, stable vibration shape and high screening efficiency.

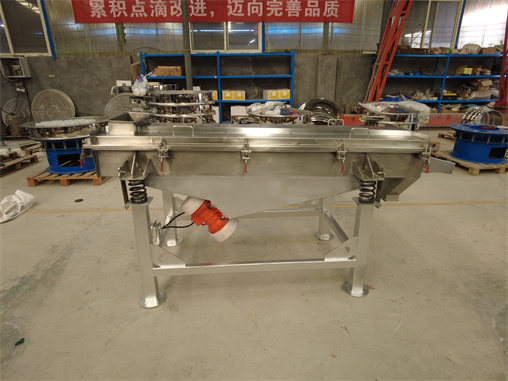

The linear vibration hoop is driven by double vibration motors. When the two vibration motors are rotated synchronously and counter-rotated, the excitation force generated by the eccentric block cancels each other in the direction parallel to the motor axis, and overlaps in the direction perpendicular to the motor axis. A resultant force, so the motion trajectory of the screen machine is a straight line. The two motor shafts have an inclination angle relative to the screen surface. Under the combined force of the exciting force and the self-gravity of the material, the material is thrown up on the screen surface and moves forward in a straight line, so as to achieve the purpose of progressive selection and classification of the material. It can be used to automate operations in the assembly line. It has the characteristics of low energy consumption, high efficiency, simple structure, easy maintenance, and fully enclosed structure without dust spillage. The highest sieving mesh number is 400 days, and 7 kinds of materials with different particle sizes can be screened.

The linear vibrating screen uses the vibration of the vibration motor as the vibration source, so that the material is thrown up on the screen and moves forward in a straight line. The material enters the feeding port of the screening machine evenly from the feeder, and produces several The oversize and undersize of the sieve are discharged from their respective outlets. It has low energy consumption, high output, simple structure, easy maintenance, fully enclosed structure, no dust spillage, automatic discharge, and is more suitable for assembly line operations.