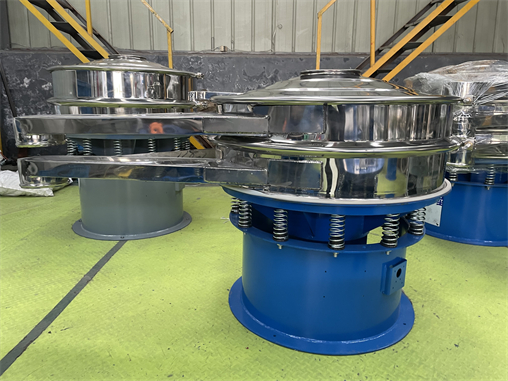

Small Stainless Steel Cosmetic Powder Vibration Sieving Machine

In order to meet different production needs, Dayong Company has continuously developed and successfully developed products of various specifications to meet the characteristics and requirements of raw material screening and filtration in various industries. Trust, Dayong Company is committed to the screening needs of every customer with the highest quality, the lowest price and the best service.

For the screening of special materials for the durable stainless steel raw material vibrating screen produced and sold by Xinxiang Dayong Company, it only takes 3 to 5 minutes to replace the screen of the corresponding size. In order to improve the screening effect of the rotary vibrating screen when screening fine materials, ultrasonic systems and other equipment can be added.

The rotary vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It takes 3-5 minutes to change the screen quickly. The rotary vibrating screen uses a vertical motor as the excitation source. The upper and lower ends of the motor are installed with eccentric weights, which convert the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined, and then transmit this motion to the screen surface. . Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface.