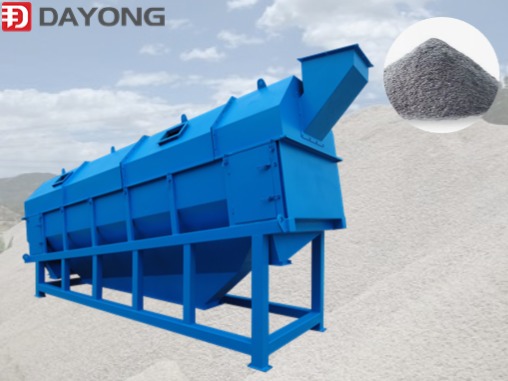

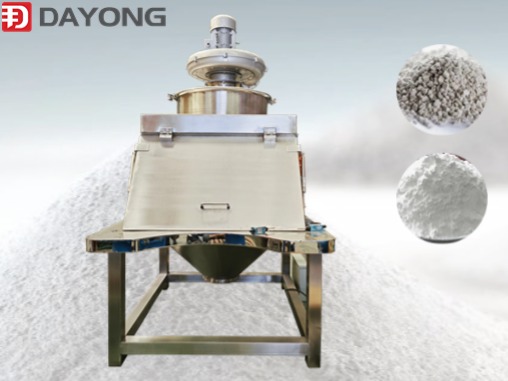

Screening of plastic particles by linear vibrating screen

Linear vibrating screens have high screening accuracy, large processing capacity, can be used for automated operations in assembly lines, and are suitable for a variety of industries.For example: In the chemical industry, linear vibrating screens play an important role in screening plastic particles. Through functions such as separation, impurity removal and classification, they improve the quality, safety and reusability of plastic products.

The linear vibrating screen requires the following steps to screen plastic particles:

1. Particle separation: Linear vibration sieve can be used to separate and screen plastic particles of different sizes to ensure that products meet the specified particle size requirements.

2. Removal of impurities: Impurities, foreign matter, fibers, etc. in plastic particles can be effectively removed through the screening function of the linear vibro sifter.This helps improve the quality and safety of plastic products.

3. Even distribution: The vibration of the linear vibrating screen can evenly distribute the plastic particles on the screen surface, avoid particle aggregation or accumulation, and ensure the uniformity of the screening effect.

4. Classification and sorting: By adjusting the screen hole size and vibration parameters, the linear vibro separater can classify and sort plastic particles in different particle size ranges to meet the needs of different products or processes.

5. Reusable waste processing: Linear vibrating screen can be used to process reusable waste plastic particles and screen them out for reprocessing and recycling.