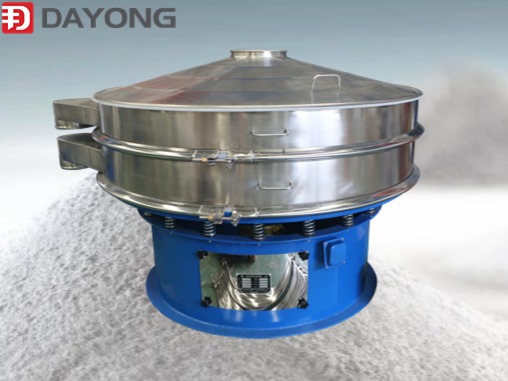

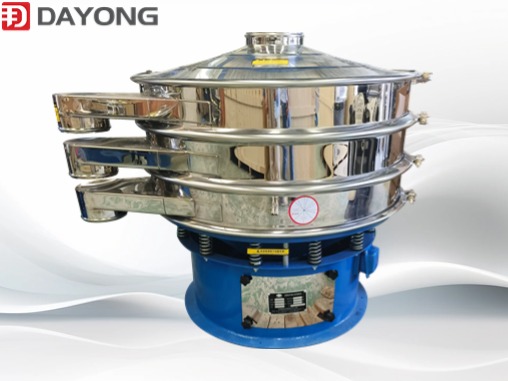

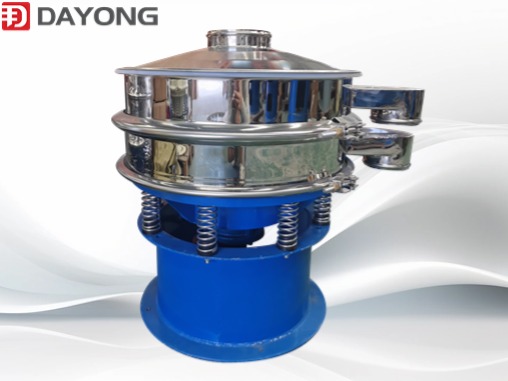

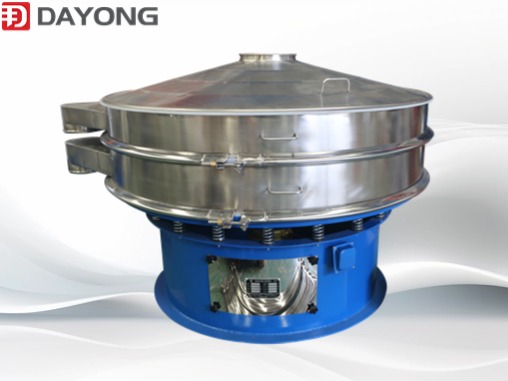

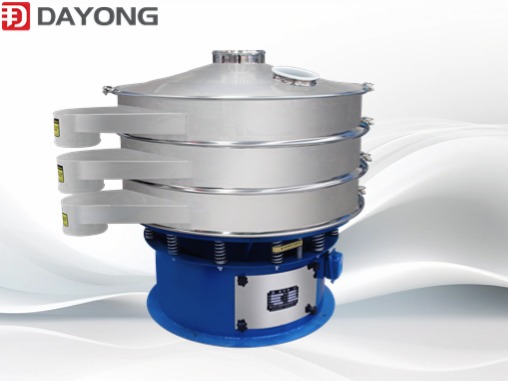

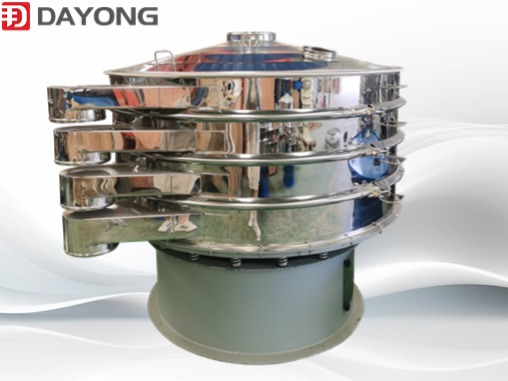

Rotary Vibrating Screen Machine In Food Industry

Rotary vibrating screen machine have small size, light weight, saving space. And vibrating screen can adjust its discharging port, coarse and fine material automatically discharged. No mesh plug, no powder flying, the smallest screen can be up to 500 mesh (28 microns), the smallest filter up to 5 microns.Single layer rotary vibration screen with unique grid design, long-term use of screen, easy to change screen mesh, only 3-5 minutes, simple operation, easy to clean.No mechanical action, easy maintenance, can be single or multi-layer, contact part of the material is made of stainless steel (except for medical use).

6.Any solid, liquid, powder, granules, slurry materials within a certain range can be screened.

The rotary vibrating screen of Xinxiang Dayong company is widely used.

1. Chemical industry: resin powder, paint, washing powder, fine powder, paint, soda ash, lemon powder, rubber, plastic and so on.

2. Abrasive, ceramic industry: alumina, quartz sand, mud, spray soil particles.

3. Food industry: sugar, salt, alkali, monosodium glutamate, milk powder, soy milk, yeast, fruit juice, soy sauce, vinegar and so on.

4. Paper industry: coating coatings, white mud, black and white liquid, waste liquid, paper liquid, waste water recovery.

5. Metallurgical industry: titanium oxide, zinc oxide, electromagnetic materials, metal powder, electrode powder.

6. Pharmaceutical industry: medicine powder, liquid medicine, medicine and other particles.

7. Environmental protection: waste, manure, waste oil, food waste water, waste water processing.