Pulp Vibrating Screen Filter Screening Machine for Paper Industry

The working principle of the vibrating screen for filtering pulp is that a motor is installed at the base of the screening machine, and eccentric weights are installed at the upper and lower ends of the motor. Horizontal, vertical, inclined), adjust the phase angle of the vibrator’s upper and lower rotating weight blocks, and the screening movement direction of the material on the screen surface will change. When the upper and lower weight blocks overlap and the phase angle is 0 degrees, the material will Divergence outward; when the phase angle of the weight block is 90 degrees, the material gathers to the center to complete the screening work.

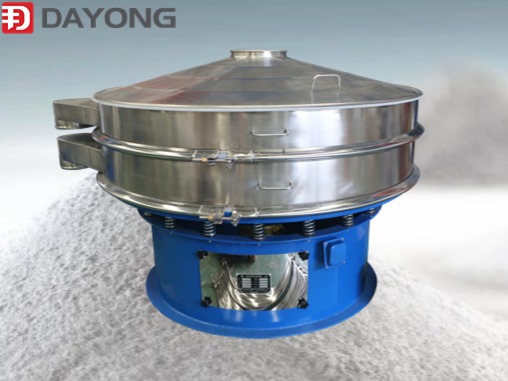

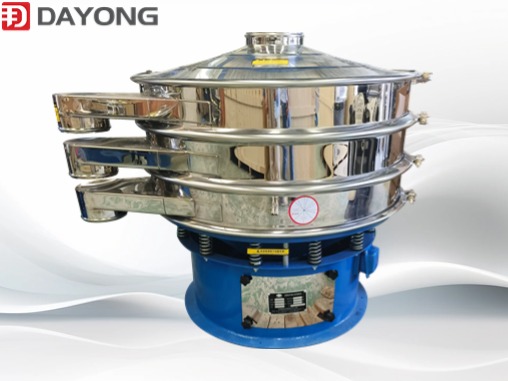

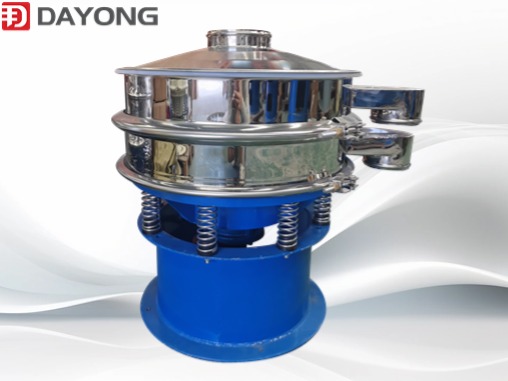

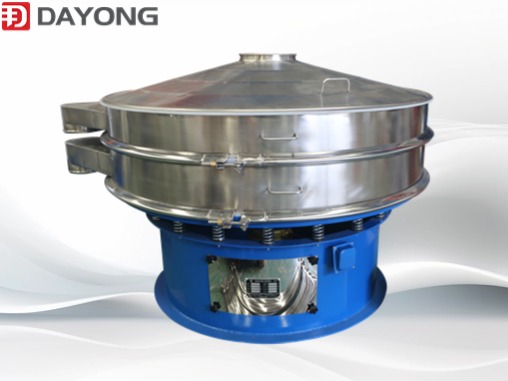

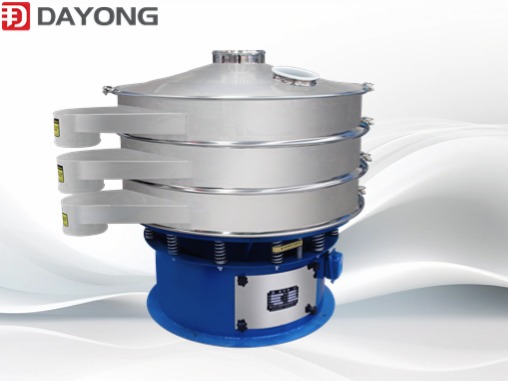

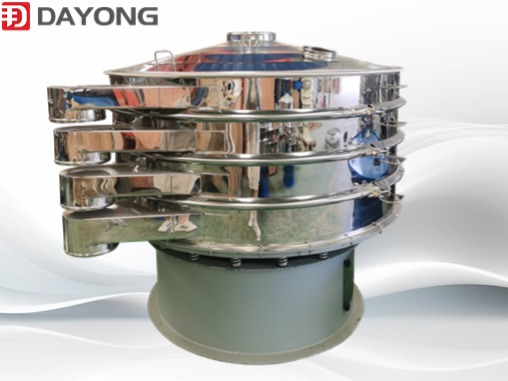

The structure of the vibrating screen produced by Dayong Company: base, vibrating motor, dust cover, spring, grid and other components. The company also produces ultrasonic vibrating screens, linear vibrating screens, mining vibrating screens, etc. to meet the diverse needs of customers. If you have any relevant questions, you can leave us a message to contact us.

The paper industry is a relatively special industry in the industry. In the early stage of most paper industries, raw materials need to be ground into pulp, such as some bark, rags and other raw materials. During the grinding process, in addition to pulp, the raw materials will contain small particle size. In order to ensure the availability of pulp, impurities such as sand, small metals, etc., need to be screened and filtered out of the impurities in the pulp, which requires a screening machine, and a vibratory sieve is a screening tool specially used for filtering and removing impurities. , to facilitate the production of paper, and to improve work efficiency, save manpower and material resources, then what is its working principle?

The working principle of the vibrating screen for filtering pulp is that a motor is installed at the base of the screening machine, and eccentric weights are installed at the upper and lower ends of the motor. Horizontal, vertical, inclined), adjust the phase angle of the vibrator’s upper and lower rotating weight blocks, and the screening movement direction of the material on the screen surface will change. When the upper and lower weight blocks overlap and the phase angle is 0 degrees, the material will Divergence outward; when the phase angle of the weight block is 90 degrees, the material gathers to the center to complete the screening work.

The structure of the vibrating screen produced by Dayong Company: base, vibrating motor, dust cover, spring, grid and other components. The company also produces ultrasonic vibrating screens, linear vibrating screens, mining vibrating screens, etc. to meet the diverse needs of customers. If you have any relevant questions, you can leave us a message to contact us.