Powder Screening Machine Separating Plastic Particles Vibrating Sieve Vibrating sieve/vibrating sieve price/vibrating screen machine/vibrating screeners

The powder sieving machine produced and sold by Xinxiang Dayong Vibration Equipment Co., Ltd. separates plastic particles. The Sieve Vibrating sieve/vibrating sieve price/vibrating screen machine/vibrating screeners is dedicated to sieving powder and plastic particles.In response to the special needs of different industries, the three-dimensional vibrating screen has a unique design, such as edge-added type, gate type, powerful type, sealed type and other different types.Screen Material Outlet is the opposite of the Over-sized material outlet and it is the outlet for all graded, screened products from the machine.

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

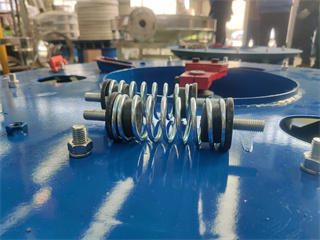

The Powder Screening Machine Separating Plastic Particles Vibrating Sieve Vibrating sieve/vibrating sieve price/vibrating screen machine/vibrating screeners source of the vibrating motor vibrating screen is the vibrating motor. Eccentric weights (unbalanced) are set on the top and bottom of the rotating shaft of the vibration motor. Under the action of the eccentric weight, the eccentric weight is transformed into horizontal, vertical and inclined three-dimensional movement. The rotating vibrating screen uses a motor to transmit the three-dimensional motion to the material on the screen. The movement trajectory of the material is changed by changing the phase angle of the up and down eccentric weight of the vibrating motor.It can be installed and used in single-layer or multi-layer combination, and the materials are divided into 2-6 levels at one time.The parts in contact with the materials are made of stainless steel 304, which is clean and hygienic and meets food requirements.In order to further improve your material throughput, we offer optional unclogging systems that will “unclog” the sieve as it is used.

We offer two main cleaning techniques that have proven their effectiveness and robustness:

Ball cleaning: a system for cleaning the lower part of the screen cloth consisting of elastomer balls that bounce off a perforated stainless steel plate. This system is especially recommended in the event of the presence of fine products that can stick to the fabric threads.

Brush cleaning: a system where the brushes are located on the fabric. It is effective in certain very specific cases, such as when particularly sticky products or products that tend to clump together are used. This system is placed directly on the sieve and the rotation of the brushes is carried out thanks to the three-dimensional movements of the sifter.