Powder Filling Machine – Milk Powder Packaging

There are many advantages to using a powder filling machine to fill milk powder. Including precise measurement, counting, etc. Xinxiang Dayong Vibration Equipment Co., Ltd. will introduce it to you in this article.

In the field of milk powder production and packaging, traditional manual packaging methods are not only inefficient, but also difficult to ensure the accuracy and hygiene standards of packaging. With the advancement of technology, powder filling machines have emerged, bringing changes to milk powder packaging. Xinxiang Dayong Vibration Equipment Co., Ltd. introduces to you.

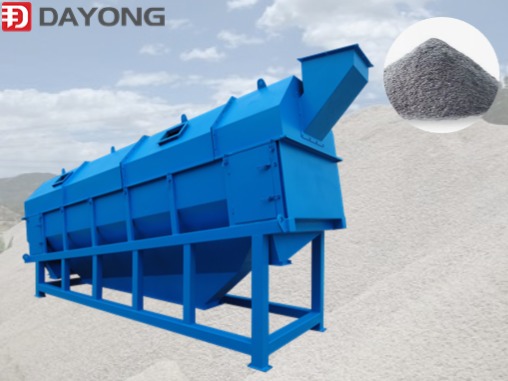

The powder filling machine has high-precision and high-efficiency filling capabilities. It adopts advanced sensors and weighing systems. This can accurately control the filling amount of milk powder, ensuring that the weight of each bag of milk powder meets the standard. This avoids errors caused by manual operation.

At the same time, the powder packng machine also has a high level of automation. The entire process from material conveying, weighing, filling to sealing is fully automated, greatly improving production efficiency.

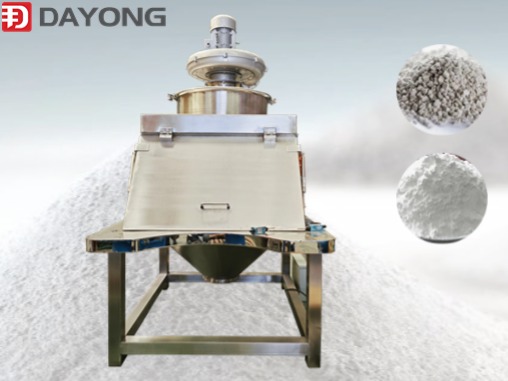

In addition, the powder filling machine also performs well in terms of hygiene standards. Its material is usually made of stainless steel, which meets food grade standards. Stainless steel material is corrosion-resistant and easy to clean.

Powder filling machines are playing an increasingly important role in the field of milk powder packaging. Xinxiang Dayong Vibration Equipment Co., Ltd. is a professional powder filling supplier. Looking forward to your consultation!