Portable Grain Linear Vibrating Sieve/Instant Noodles Vibration Sieve/Salt Linear Type Vibration Sieve Vibrating Motor

Portable Grain Linear Vibrating Sieve/Instant Noodles Vibration Sieve/Salt Linear Type Vibration Sieve Vibrating Motor produced and sold by Xinxiang Dayong Vibrating Equipment Co., Ltd. is specially used for screening grain / instant noodles.Low energy consumption, low noise and long service life of the screen.High screening accuracy, large processing capacity and simple structure.The screen replacement process is simple and the equipment is easy to operate.Reasonable matching of the screen mesh can screen out a variety of products of different specifications at one time.

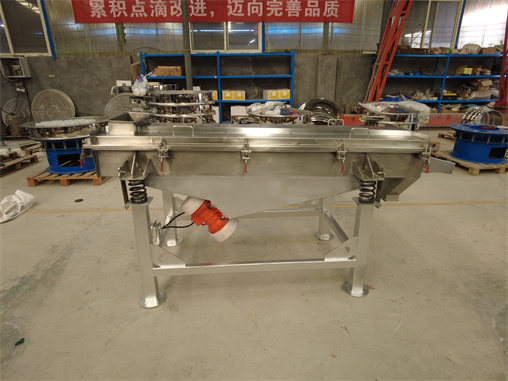

Material: stainless steel, carbon steel

Model: DZSF515, DZSF520, DZSF525, DZSF1020, DZSF1025, DZSF1030

Price: $1000-$1500

Portable Grain Linear Vibrating Sieve/Instant Noodles Vibration Sieve/Salt Linear Type Vibration Sieve Vibrating Motor Linear vibrating screen is used for fine powder screening, especially suitable for difficult materials. Advantages:The motor is used as the power source to make the material move forward in a straight line while being thrown up on the screen. It can be matched with a single-layer or multi-layer screen to achieve the purpose of dehydration, impurity removal, inspection, etc. It has the functions of grading and conveying. The product has high screening accuracy, large processing capacity, simple structure, low energy consumption, low noise, long service life of the screen, good sealing, little dust spillage, convenient maintenance, and can be used for automated operations in assembly line production. It is suitable for screening various dry powder materials with particle size of 0.074-5mm, moisture content less than 70%, and no stickiness. The feeding particle size is not more than 10mm.All parts of the screen body are welded by rolled steel plates and profiles (parts of the body are connected by bolts). The overall rigidity is good, firm and reliable.Fully enclosed structure, automatic discharge, convenient maintenance, more suitable for assembly line operation.All incoming materials are automatically discharged, and there is no material stored in the machine.