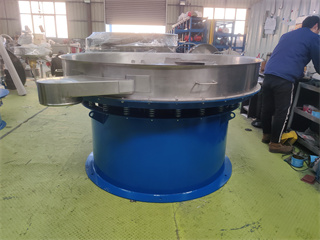

Plastic Pellet Vibro Sieve/vibration Separation Screening Machine /screen asphalt/sieve flour/sieves price/sieves vibro/Vibrating sieve

Plastic Pellet Vibro Sieve/vibration Separation Screening Machine /screen asphalt/sieve flour/sieves price/sieves vibro/Vibrating sieve produced and sold by Xinxiang Dayong vibration equipment Co., Ltd. is specially used to screen cassava powder, cocoa powder / coconut powder.The circular vibrating screen of Xinxiang Dayong Company has high screening accuracy and high working efficiency, and is suitable for any particle, powder and slurry.

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

The power source of Plastic Pellet Vibro Sieve/vibration Separation Screening Machine /screen asphalt/sieve flour/sieves price/sieves vibro/Vibrating sieve motor vibrating screen is vibrating motor. Eccentric weights (unbalanced) are set at the top and bottom of the vibration motor’s rotating shaft. Under the action of the eccentric weight, the three-dimensional movement of horizontal, vertical and inclined is transformed. A rotary vibrating screen uses a motor to transmit three-dimensional motion to the material on the screen. The movement trajectory of the material is changed by changing the phase angle of the upper and lower eccentric weights of the vibration motor.It only takes 3 to 5 minutes to replace the corresponding size screen. In order to improve the screening effect of the rotary vibrating screen when screening fine materials, ultrasonic systems and other equipment can be added.

The grid of the rotary vibrating screen will not be blocked, it can be screened to 500 mesh or 0.028mm, and the coarse waste of impurities can be automatically discharged. Can work continuously.

It only takes 3-5 minutes to change the screen by rotating the vibrating screen. Small size, easy to operate. The screen machine has five layers at most, and it is recommended to use three layers more. At the same time, the number of layers can also be selected according to the material to be screened.