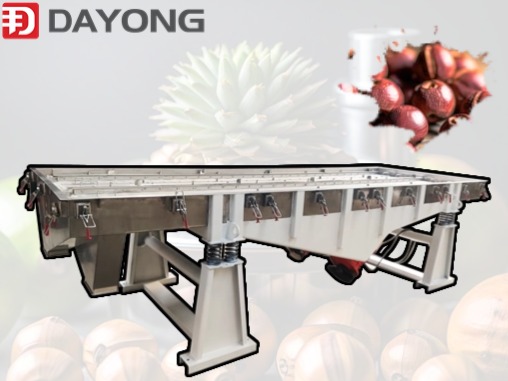

Pharmaceutical Medicine Pepper Vibrating Screen Sieve Linear Sieving Machine/Pepper Sieve Machine/Medicine Sieve Machine

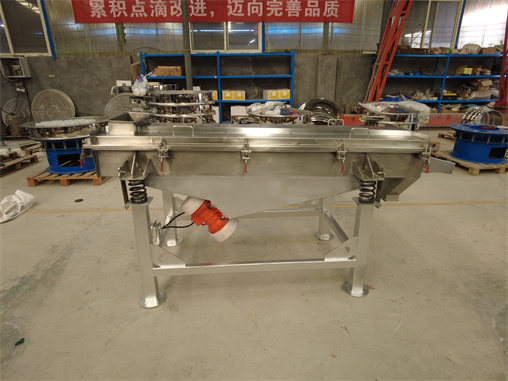

Pharmaceutical Medicine Pepper Vibrating Screen Sieve Linear Sieving Machine/Pepper Sieve Machine/Medicine Sieve Machine produced and sold by Xinxiang Dayong vibration equipment Co., Ltd. is dedicated to screening pharmaceutical pepper.When screening materials, the materials should be evenly put into the feeding port to ensure that the materials on the screen surface are evenly distributed. When the material falls, there should be no big impact to avoid damage to the screen. In special cases (such as a large difference in material particle size, a large material proportion, etc.), a thicker screen should be added to the feed port for buffering.

Material: stainless steel, carbon steel

Model: DZSF515, DZSF520, DZSF525, DZSF1020, DZSF1025, DZSF1030

Price: $1000-$1500

When the two Pharmaceutical Medicine Pepper Vibrating Screen Sieve Linear Sieving Machine/Pepper Sieve Machine/Medicine Sieve Machine motors are rotated synchronously and in opposite directions, the exciting force generated by the eccentric block offsets each other in the direction parallel to the motor shaft, and superimposes in the direction perpendicular to the motor shaft, so the motion trajectory of the screen machine is a straight line. The two motor shafts have a tilt angle in the vertical direction. Under the action of the exciting force and self-weight of the material, the material jumps on the screen surface or moves straight forward, so as to achieve the purpose of screening and grading the material.Turn on the power switch, confirm that the vibration motor rotates in the opposite direction synchronously, and run idly for 10-20 minutes. If there is any abnormal sound during operation, the equipment should be shut down quickly for inspection and processing. After the equipment is running normally, a small amount of material to be screened can be put into the screen machine through the feeding port, confirm that the material travels in the direction of the discharging port, and then gradually increase to the required and acceptable feeding amount.