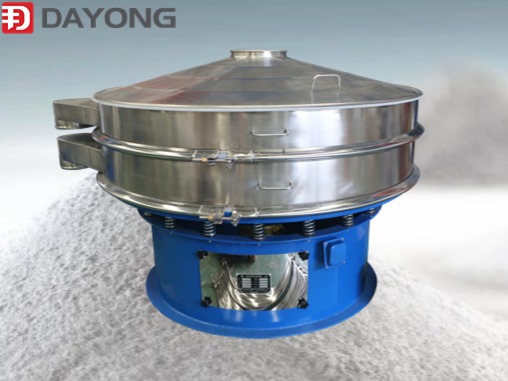

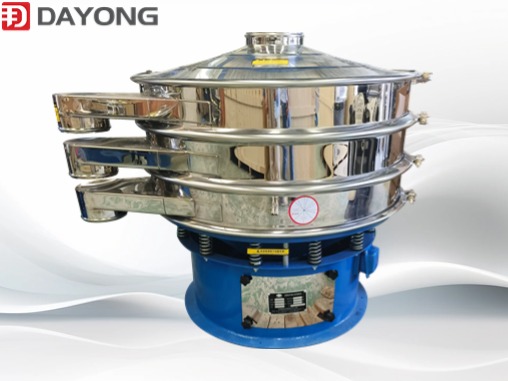

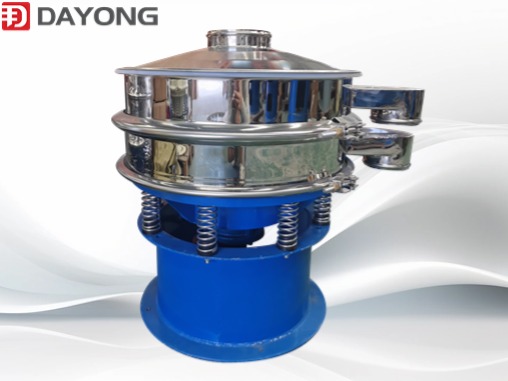

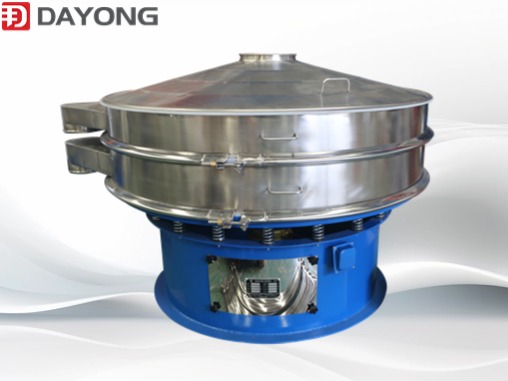

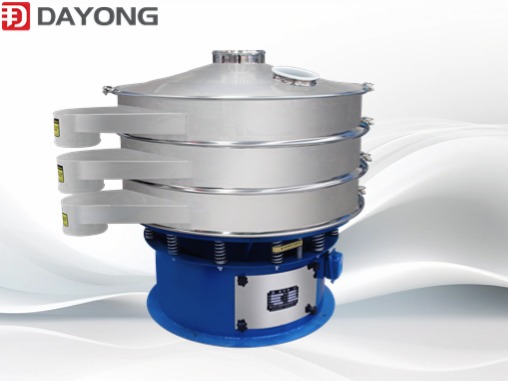

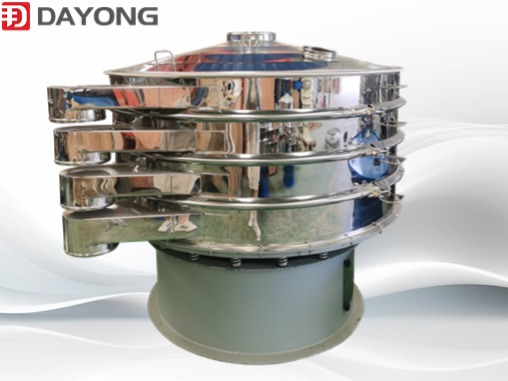

Oscillating Sieve Machine For Particle/Stainless Steel304 Food Processing Oscillating Sifter / Vibrating Sieve Shaker For Msg

Oscillating Sieve Machine For Particle/Stainless Steel304 Food Processing Oscillating Sifter / Vibrating Sieve Shaker For Msg is a new type of equipment specially produced by Xinxiang Dayong Company for the powder screening problem. The components form a complete vibrating screen that can screen, classify and filter, ultrasonic vibrating screen, linear vibrating screen, mining vibrating screen, etc., to meet the diverse needs of customers.

Oscillating Sieve Machine For Particle/Stainless Steel304 Food Processing Oscillating Sifter / Vibrating Sieve Shaker For Msg is a new type of equipment specially produced by Xinxiang Dayong Company for the powder screening problem. The components form a complete vibrating screen that can screen, classify and filter, ultrasonic vibrating screen, linear vibrating screen, mining vibrating screen, etc., to meet the diverse needs of customers.

The stainless steel vibrating screen is mainly used, and its screen is divided into stainless steel woven screen and punched screen. With the modernization of preparation production and the improvement of production efficiency, users should select the accuracy of sieving according to the purpose of sieving to remove impurities, classify, filter or other. Secondly, the size of the machine model is determined according to the processing capacity. For different processing capacity, Dayong Company has professionally developed different types of screening machines such as DY-400/DY-600/DY-800.

The working principle of the vibrating screen is that the vibration of the vibrator is excited by the operation of the motor, and the vibration part is vibrated in a complex rotary shape through the connection of the spring. Vertical, inclined), adjust the phase angle of the upper and lower rotating weight blocks of the vibrator, which can change the movement trajectory of the material on the screen surface. When the upper and lower weight blocks overlap and the phase angle is 0 degrees, the material diverges from it to the outside; when When the phase angle of the weight block is 90 degrees, the material will gather to the center to complete the screening work.