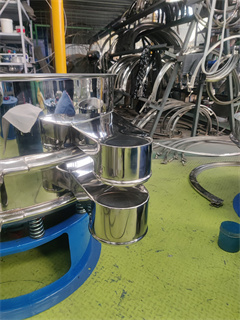

Nutraceutical Grading Machine Calcium Tablet Rotary Vibration Screener Manufacture/4 deck vibrating screen/powder vibration sieve factory/rotary screen

Xinxiang Dayong Vibrating Equipment Co., Ltd. produces and sells Nutraceutical Grading Machine Calcium Tablet Rotary Vibration Screener Manufacture/4 deck vibrating screen/powder vibration sieve factory/rotary screen, which is dedicated to screening calcium and powder.Compared with other metal springs, it has the characteristics of long service life, corrosion resistance, stable operation, low noise and little impact on the foundation.

DY-600 Vibrating Screen /DY-800 Vibrating Screen/DY-1000 Vibrating Screen

Price:598$-898$

Nutraceutical Grading Machine Calcium Tablet Rotary Vibration Screener Manufacture/4 deck vibrating screen/powder vibration sieve factory/rotary screen is a high-precision fine powder screening machine. The working principle of the rotary vibrating screen is that the eccentric hammers installed at the top and bottom of the motor convert the rotating motion of the motor into horizontal, vertical and inclined three-dimensional motion, and then transfer this motion to the screen surface to achieve the purpose of classification, filtration and removal Impurities.The rotary vibrating screen is small in size and easy to move. It adopts integral sealing structure design. And it is suitable for screening work in many industries.The rotary vibrating screen separator is easy to install and can be operated by one person. The horizontal distance between the entrance and exit is small, which is convenient for machine layout.In order to further improve your material throughput, we offer optional unclogging systems that will “unclog” the sieve as it is used.

We offer two main cleaning techniques that have proven their effectiveness and robustness:

Ball cleaning: a system for cleaning the lower part of the screen cloth consisting of elastomer balls that bounce off a perforated stainless steel plate. This system is especially recommended in the event of the presence of fine products that can stick to the fabric threads.

Brush cleaning: a system where the brushes are located on the fabric. It is effective in certain very specific cases, such as when particularly sticky products or products that tend to clump together are used. This system is placed directly on the sieve and the rotation of the brushes is carried out thanks to the three-dimensional movements of the sifter.

Finally, we also offer an ultrasonic cleaning system.