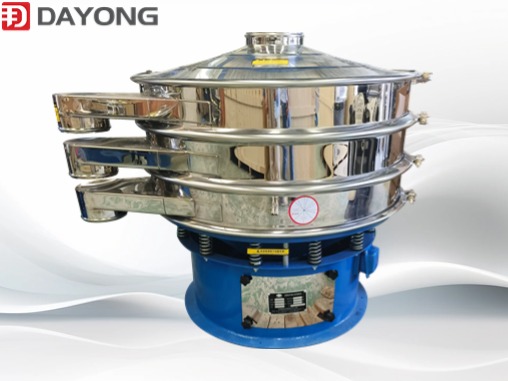

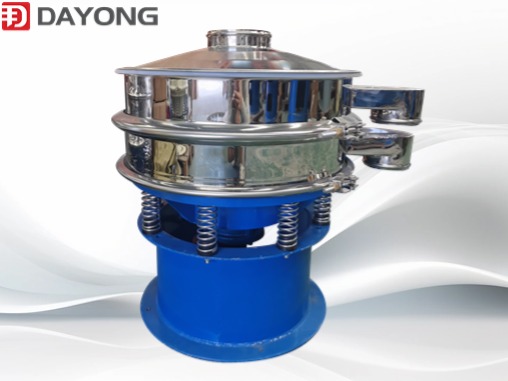

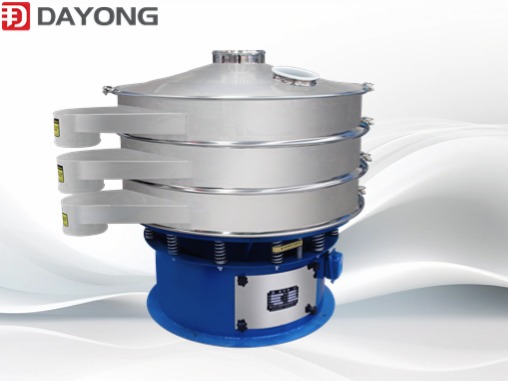

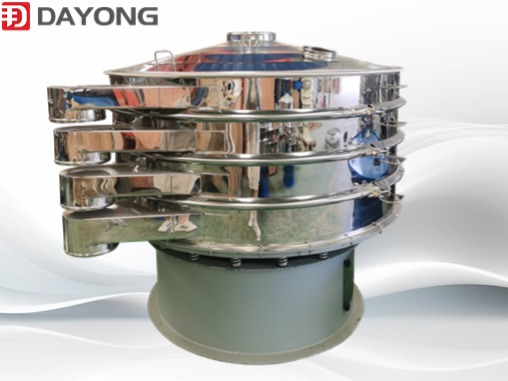

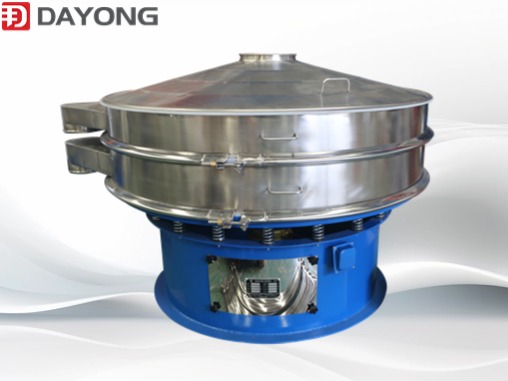

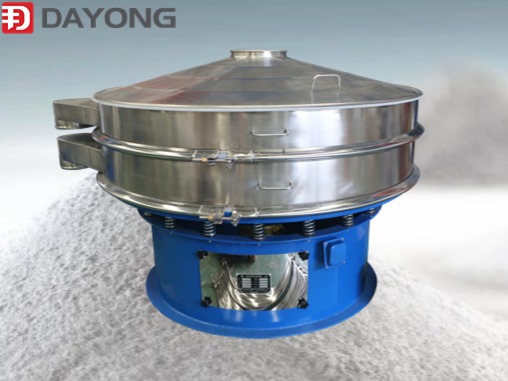

Mini Mining Sand Sieving Vibrating Screen For Construction

With the DY series vibrating screen produced by Dayong Company, the products can be separated and screened continuously and accurately, and five kinds of products with different particle sizes can be separated and screened with one multi-layer use without the phenomenon of inconsistency in size. Different specifications of equipment can be customized according to customer needs to meet the diverse needs of users.

Vibrating screen is a low-noise, high-efficiency high-precision fine powder screening machine. A quick screen change takes 3-5 minutes. Fully enclosed, suitable for screening and filtration of granules, powders

and mucus. The vibrating screen is excited by a vertical motor. The upper and lower ends of the motor are equipped with eccentric blocks, which convert the rotary motion of the motor into horizontal, vertical and inclined three-dimensional motion, and then transmit the motion to the material on the screen surface. Adjusting the phase angle of the upper and lower ends can change the movement trajectory of the materialon the screen surface. The mesh number of some materials is relatively small, such as the case of 40-80 mesh, so it is necessary to appropriately extend the trajectory of the running material on the screen surface to achieve a good screening effect. If the mesh number of the material is required to be more than 80 mesh, it is necessary to extend the running track of the material on it. The general angle is between 65 and 85.The adjustment of the motor angle, when we face the vibration motor, the upper counterweight is in the left-hand direction, and the lower counterweight is in the left-hand direction. The counterweight is in the right-hand direction, and the angle between the two counterweights facing your body is what we call the angle