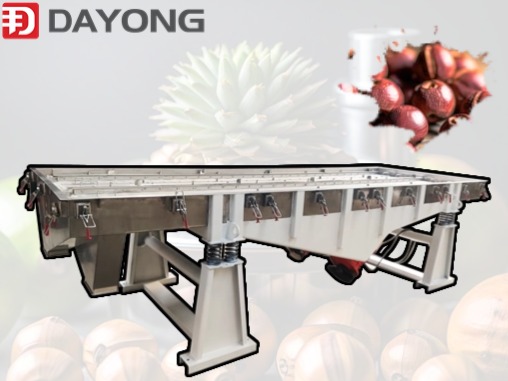

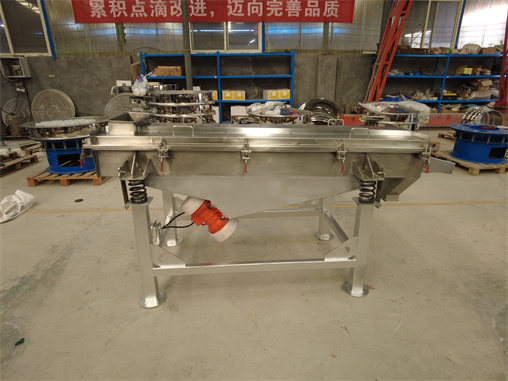

Manufacturer High Capacity Chemical Industries Linear Vibro Sieve Machine For Plastic Granule

Xinxiang Dayong Company has been focusing on the manufacture of screening and conveying equipment for 11 years. The Manufacturer High Capacity Chemical Industries Linear Vibro Sieve Machine For Plastic Granule produced and sold by Xinxiang Dayong Company has a wide range of applications.

The high-efficiency linear vibrating screen is driven by dual vibration motors. When the two motors rotate synchronously and reversely, under the influence of the resultant force of the exciting force, the exciting force generated by the eccentric block is parallel to the axis of the motor and eliminated relative to the screen plate. The iron powder is thrown up by its own weight and jumps linearly on the sieve plate to screen and classify the iron powder. Applied to the assembly line to realize automatic operation.

Xinxiang Dayong Company has been focusing on the manufacture of screening and conveying equipment for 11 years. The Manufacturer High Capacity Chemical Industries Linear Vibro Sieve Machine For Plastic Granule produced and sold by Xinxiang Dayong Company has a wide range of applications.

The high-efficiency linear vibrating screen is driven by dual vibration motors. When the two motors rotate synchronously and reversely, under the influence of the resultant force of the exciting force, the exciting force generated by the eccentric block is parallel to the axis of the motor and eliminated relative to the screen plate. The iron powder is thrown up by its own weight and jumps linearly on the sieve plate to screen and classify the iron powder. Applied to the assembly line to realize automatic operation.

According to the needs of the mechanical structure and process parameters, the vibrator is located on the top of the center of gravity of the screen box. This arrangement makes the screen have an elliptical trajectory at the material end, and the discharge end is still elliptical. The screen adopts flange type vibrator, which consists of two motors. Do reverse self-synchronous rotation, so as to achieve the purpose of grading and screening flour and other materials.

Linear vibrating screen consists of screen box, screen frame, vibration motor, shock absorber and base. Two identical vibration motors are attached to the top of the screen box as vibration providers. They rotate synchronously in opposite directions. An eccentric mass driven by a motor provides centrifugal force, the component of which moves back and forth in the casting direction. Therefore, the screen device supported by the shock absorber can move linearly. The sand on top moves straight forward when thrown upwards. When the sand falls into the screen frame again, the sand will move forward rapidly and penetrate the screen in a fluffy state. All you need to do is choose the right screen for your linear vibrating screen to get the ideal screening performance.