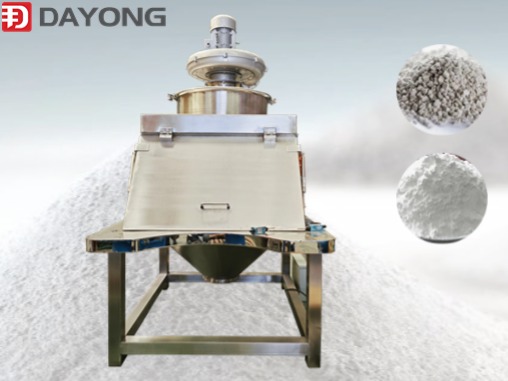

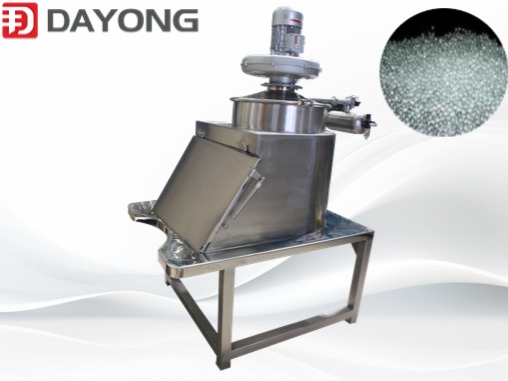

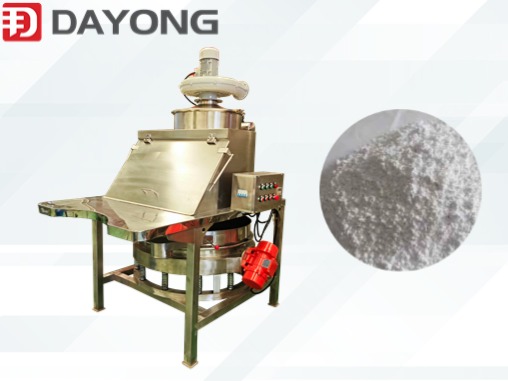

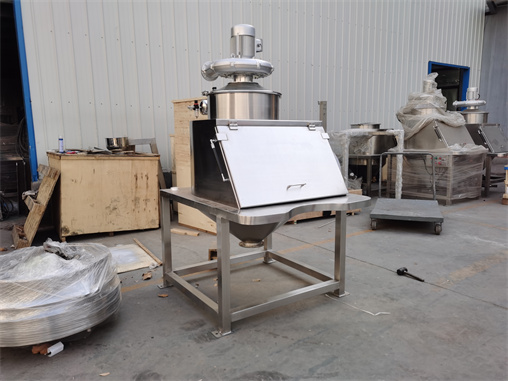

Low Noise Starch Powder Dust Free Dumping Hopper For Bulk Material

The dust-free feeding station is suitable for unpacking, placing, screening, and unloading large, medium, and small bag materials in industries such as pharmaceuticals, chemicals, food, and battery materials. Due to the function of the dust collection fan during unpacking, it can prevent material dust from flying everywhere. When the material is unpacked and poured into the next process, it only needs to be manually unpacked and directly put into the system. The material passes through the vibrating screen, which can intercept large blocks of material and foreign objects, ensuring the discharge of particles that meet the requirements. It is composed of components such as a feeding platform, unloading silo, dust removal system, hopper/vibrating screen, etc.

Features of dust-free feeding station: 1) Comply with GMP production specifications, and prevent dust from flying during work! 2) It can be flexibly connected to the next process (discharge silo can be connected to equipment such as screw conveyor, vacuum feeding machine, or direct mixing machine)! 3) The height design of the dust-free feeding table conforms to ergonomics, making it convenient for workers to stand and work, reducing labor intensity! 4) High feeding efficiency! 5) Small footprint, can be changed to a mobile or fixed stand according to actual situation! The above is a brief description of the circular vibration machinery for the dust-free feeding station. If you have any material feeding needs, please consult! Working principle of dust-free feeding station: The dust-free feeding station is composed of feeding platform, suction dust removal device, discharge bin, and other components!