Linear vibrating screen for screening bentonite

Xinxiang Dayong Vibration Equipment Co., Ltd. has successfully delivered a 20 mesh linear vibrating screen. The advantages of linear vibrating screen are fully reflected in the screening process of bentonite. This article will provide you with a detailed explanation.

Recently, Xinxiang Dayong Vibration Equipment Co., Ltd. successfully delivered a 20-mesh linear vibrating screen. It is used on the production line of a bentonite processing company. The equipment has won high recognition from customers for its efficient and stable screening performance and excellent quality.

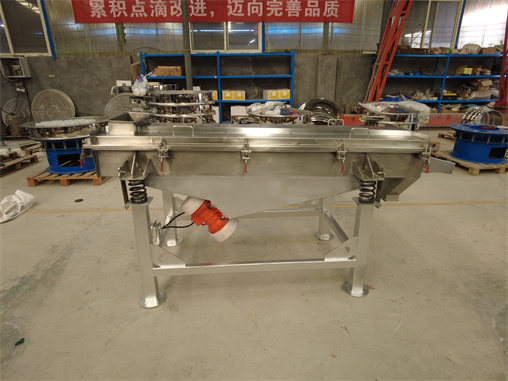

The advantages of the linear vibrating sieve are fully reflected in the bentonite screening process:

High screening accuracy: The 20-mesh screen can effectively screen out impurities in the bentonite to ensure the quality of the finished product.

Large processing capacity: The equipment runs smoothly, the material moves linearly on the screen surface, and the screening efficiency is high, which can meet the needs of customers for mass production.

Good sealing: The equipment supports customization. The fully enclosed structure is adopted to effectively prevent dust from overflowing.

Stable operation and low noise: The equipment uses high-quality parts, runs smoothly and reliably, has low noise, and extends the service life of the equipment.

Easy maintenance: The equipment has a simple structure, is easy to disassemble and clean, and reduces maintenance costs.

The customer said that since it was put into use, the linear vibro sifter has been running stably, the screening effect is remarkable, and it has effectively improved production efficiency and product quality. Xinxiang Dayong Vibration Equipment Co., Ltd. always adheres to customer demand-oriented, continuously develops and innovates, and provides customers with high-quality vibration screening equipment and solutions.