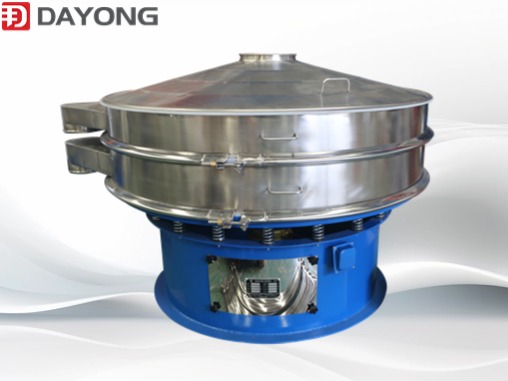

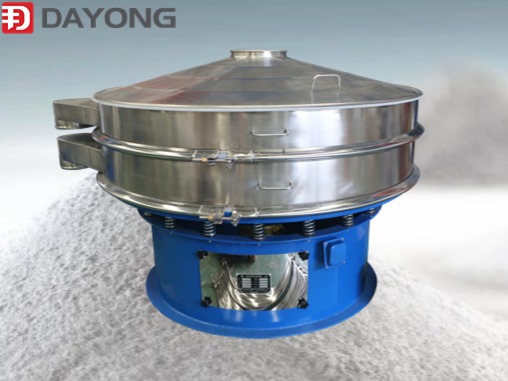

Industrial Sieve Circular Shaker For Pharmaceutical Industry/Vibrating Screen

The use of vibrating screens in pharmaceuticals has very strict requirements.

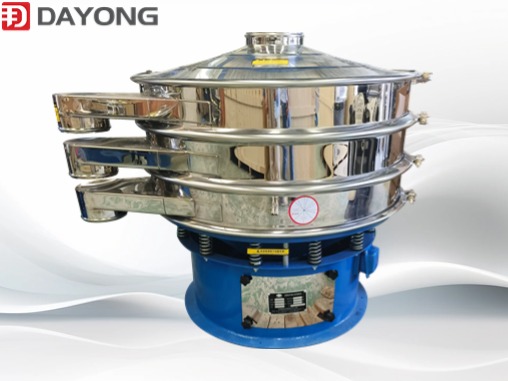

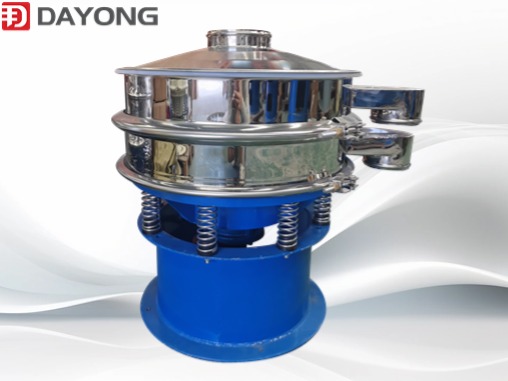

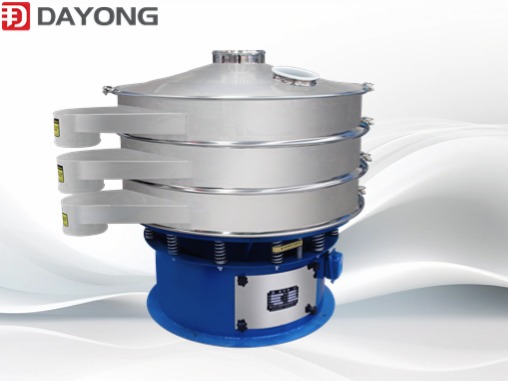

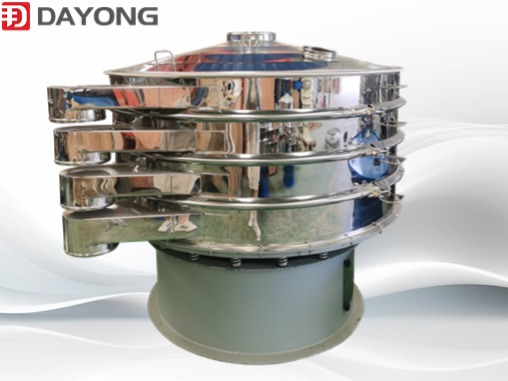

The pharmaceutical industry rotary vibrating screen produced by Dayong Vibration Equipment Co., Ltd. is a high-precision fine powder screening machine. It has low noise and high efficiency. It takes 3-5 minutes to quickly change the screen. It has a fully enclosed structure and is suitable for particles, powder and mucus and other materials for sieving and filtration. A bouncing ball is the most common cleaning device in the vibrating screen. Its shape is round, and the material can be divided into two types: rubber material and silicone material. for the purpose of clearing the network.

At the same time, the company supports customized services. Dayong will provide you with better services with the highest enthusiasm to meet your needs, which is Dayong’s unremitting pursuit.

As one of the most important commodities to ensure human health, “drugs” have received more and more attention, and higher and higher requirements have been placed on the variety, quality, and effects of drugs.

The pharmaceutical industry also has strict requirements on the screening of materials. The most basic thing is that the vibrating screening equipment used in the pharmaceutical industry must be made of stainless steel 304 or even 316. The parts in contact with the material are not allowed to be contaminated by impurities, so the rubber parts must also meet the requirements. Food-grade hygiene standards (silica gel), and the screening equipment required by the pharmaceutical industry must pass GMP production standards. The use of vibrating screens in pharmaceuticals has very strict requirements.

The pharmaceutical industry rotary vibrating screen produced by Dayong Vibration Equipment Co., Ltd. is a high-precision fine powder screening machine. It has low noise and high efficiency. It takes 3-5 minutes to quickly change the screen. The fully enclosed structure is suitable for granules, powder and mucus and other materials for sieving and filtration. The rotary vibrating screen uses a vertical motor as the excitation source. The upper and lower ends of the motor are installed with eccentric weights, which convert the rotary motion of the motor into three-dimensional motion of horizontal, vertical and inclined, and then transmit this motion to the screen surface. . Adjusting the phase angle of the upper and lower ends can change the movement track of the material on the screen surface.

On the other hand, it is the effect of cleaning the screen. There are many viscous materials in the drug series, and these materials are easy to adhere during the screening process, and the blocking of the screen affects the screening accuracy and output. The vibrating screen is equipped with bouncing balls. It is the most common net cleaning device. Its shape is round, and the material can be divided into two types: rubber material and silicone material. Its working principle is that it is evenly distributed on the pallet, generally 5-8 within ten centimeters. When the screen is vibrating and sieving, the bouncing ball also jumps and hits the screen, so as to achieve the purpose of cleaning the screen.

At the same time, the company supports customized services. Dayong will provide you with better services with the highest enthusiasm to meet your needs, which is Dayong’s unremitting pursuit.